Larger Displacement:

Longer Stroke or Bigger Bore?

Having been in the business of building custom, high performance and race engines since the mid 70’s I am often perplexed by the fact that after spending huge amounts of money on cars, most owners are prepared to give up their engines to “some tuner” for major modifications without having a basic understanding of what they are about to receive. Would you allow someone to do work on your heart without a second opinion, or at the very least, a full understanding of the treatment and prognosis?

I read about many of these high performance Porsche engine builds but I never read about why they choose a particular configuration or specification over another. Turbo builds all seem to be about massive amounts of horsepower and who can make the most. Now GT3 builds all seem to be about displacement size. Some performance figures that are “sold” cannot be achieved unless Nitrous is used. These levels of performance defy logic and the laws of physics.

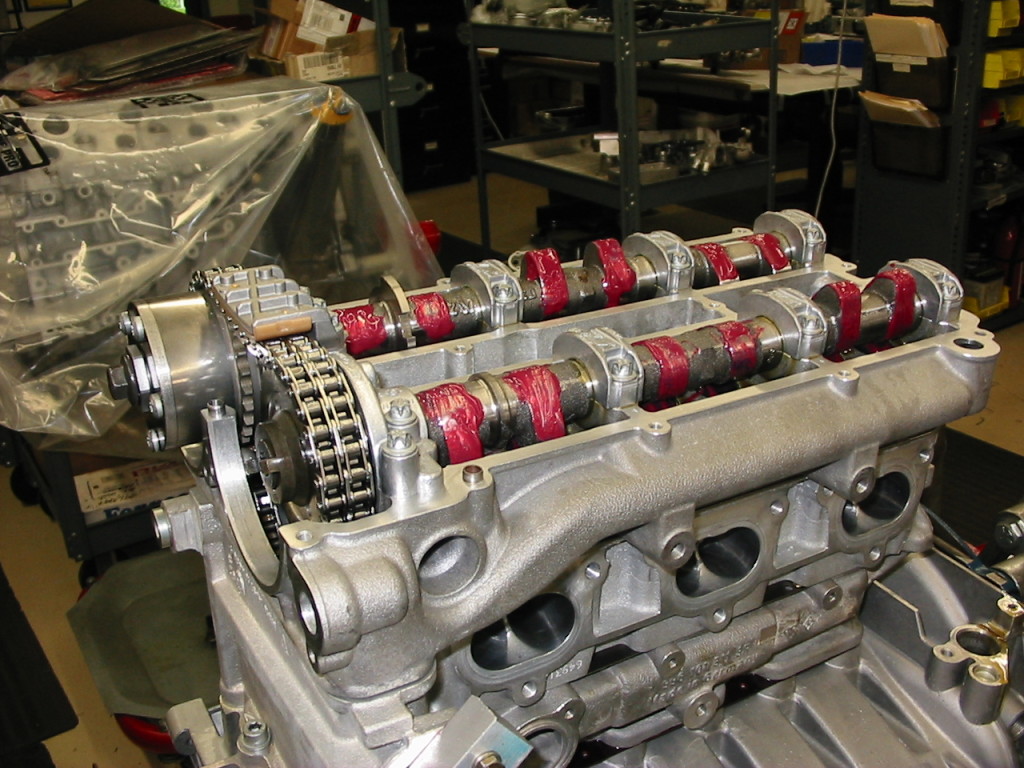

I’ll leave the turbo builds for another time and focus on the normally aspirated GT3 engine. These engines come stock from Porsche as a 3.6L or 3.8L. Both have the same size stroke, 76.40mm and bores sizes of 100.00mm and 102.70mm. Recently Porsche released the 4.0L engine which increased the stroke to 80.40mm and keep the 102.70mm bore. Why? I cannot say why Porsche picked these sizes and configuration, but I can tell you there are often options and these options change the engines performance. This always seems to be missing in write ups about someone’s engine build. Unfortunately, this has been the long standing issue with the Porsche aftermarket. Most of it is catalog work with parts and services brought in from the outside and sold to unsuspecting customers. An engine is only the sum of its parts and the labor work included. That includes all of the machine repair labor along with the assembly labor, making sure the repair machining is done to the lowest tolerances possible, the assembly work done after all parts are cleaned, inspected , measured and documented. I’m sure you wouldn’t want your heart surgeon going about his work the same way many of these engines are built.

I won’t go into too much detail so I can touch on as many parameters as possible that all play a big part in an engines performance.

Long stroke, big bore, both, short or long rods, are the areas of an engine that require updating when any of these configurations are changed.

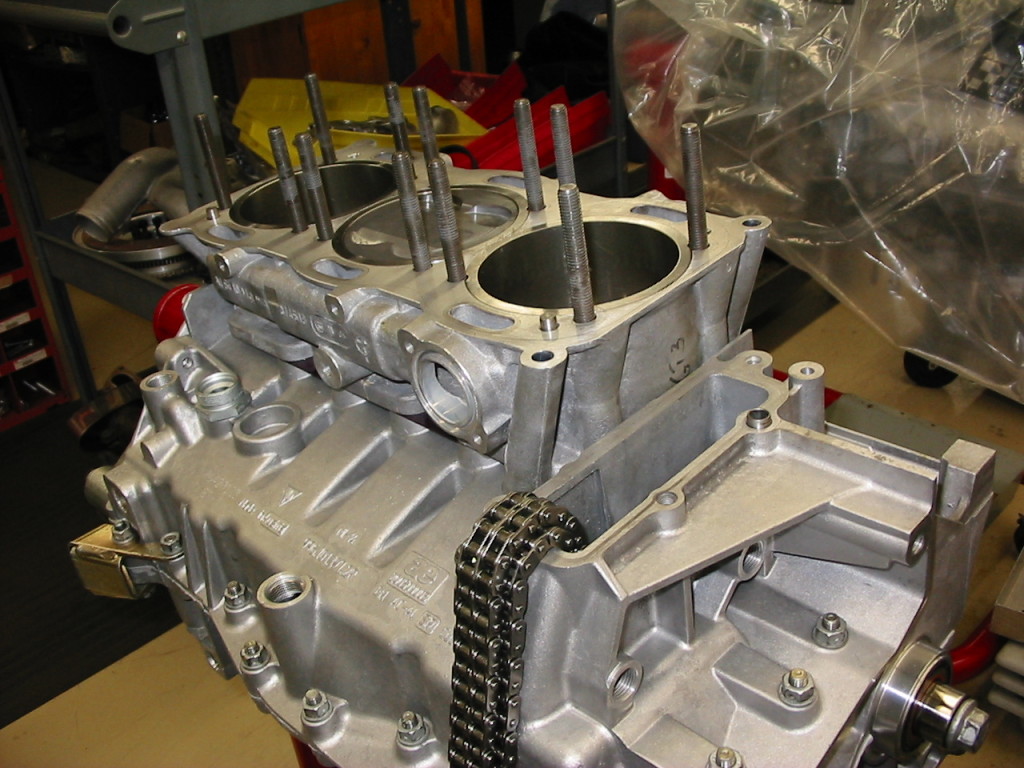

So, let’s first talk about increasing the engines displacement. This can be done within certain limits by either increasing the crankshaft stroke, it’s up and down dimensions or the engines bore size, the diameter of the cylinder. These engines first came as a 3.6L, 100.00mm bore and a 76.40mm stroke. Soon after the engine displacement was increased to 3.8L by increasing the bore size to 102.70mm. It was an easy change by swapping the cylinder liners and pistons. Not to discount all of the work involved. Then came the 4.0L engine. This changed only the crankshaft dimensions to 80.40mm and kept the cylinder bore size to 102.70mm. That’s the background. Also note, I’m only talking about GT3 street engines, not race engines.

The aftermarket jumped all over this and increased the engines displacement to 3.8L, 3.9L, 4.0L and now 4.2L. Which one should you choose? It all depends upon your performance requirements. Any of these engines sizes can be achieved by either increasing the bore or stroke or both. Most are built with “off the shelf” parts. So the limits then become 3.8L, 3.9L and 4.0L. These are all bore only changes using the stock stroke of 76.40mm.

3.6L (3600.9cc ) 100.00mm x 76.40mm

3.8L (3798 cc ) 102.70mm x 76.40mm

3.9L (?) 104.00mm + x 76.40mm. This is a non typical Porsche size that would use a 104.00mm + bore size

4.0L (4000.3cc ) 105.40mm x 76.40mm

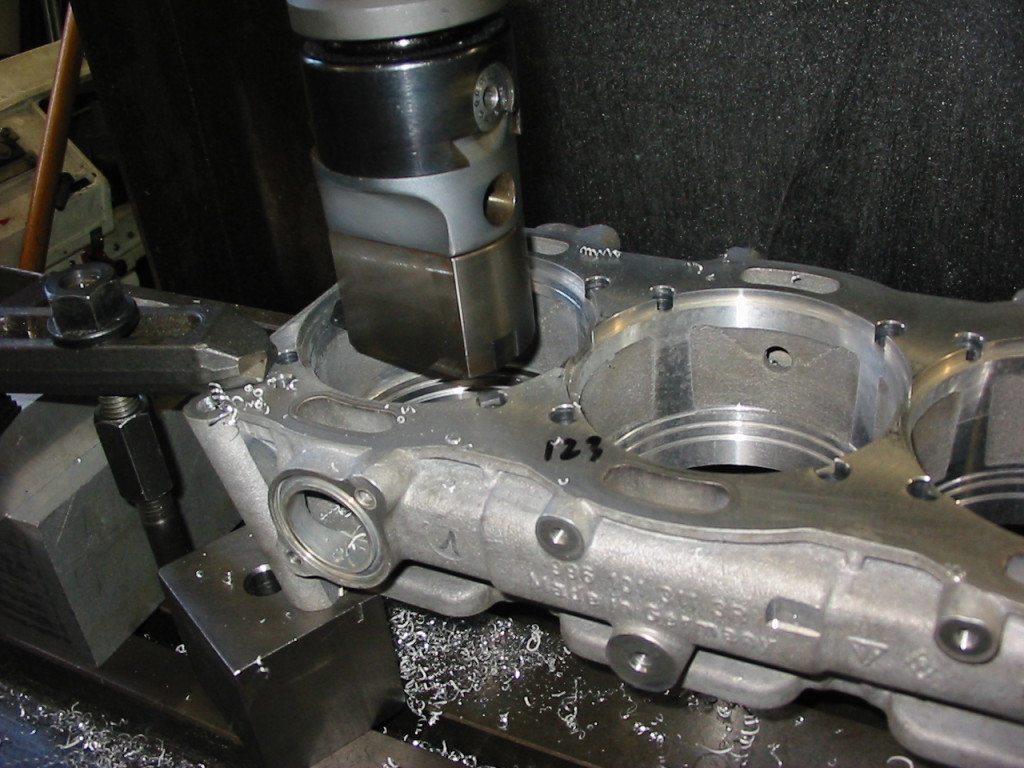

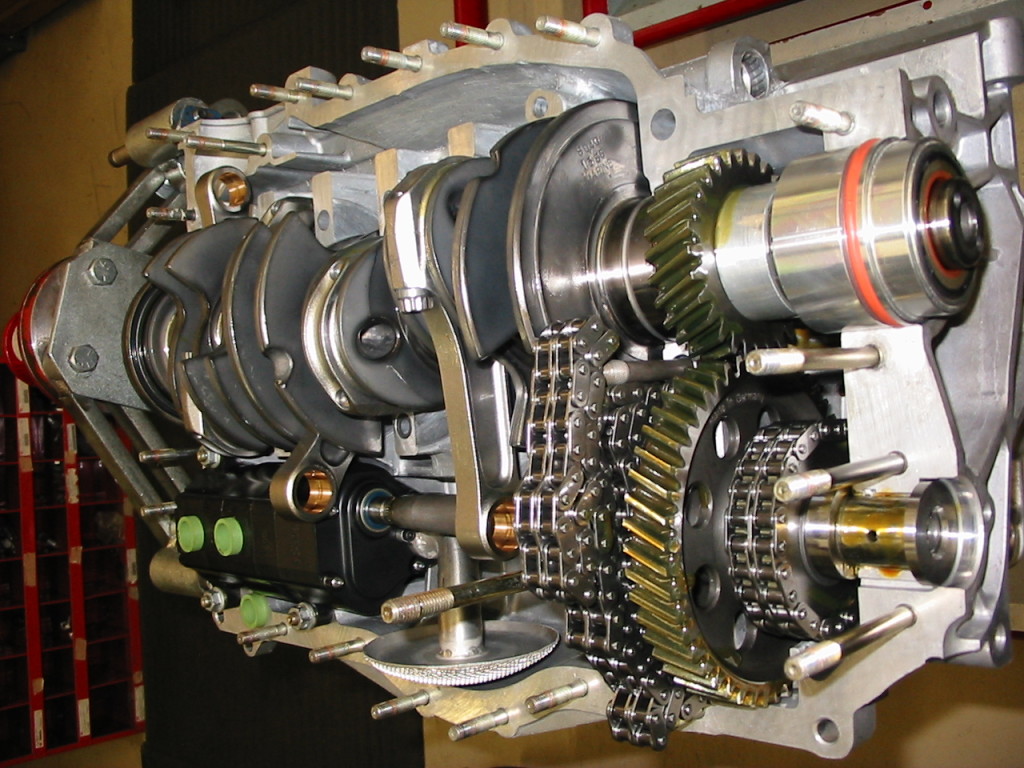

With the oil pump inside the engine case below the crankshaft there is a limit on the stroke as the connecting rods in the rear of the engine have to clear the pump body. As you increase the stroke the design of the connecting rods becomes important, if just to clear the pump. Most “off the shelf” rods that are not designed for a particular engine build will limit the stroke possible. The Oil pump requires clearances which require removing material from the pump body. This is one of the limitations of buying off the shelf parts.

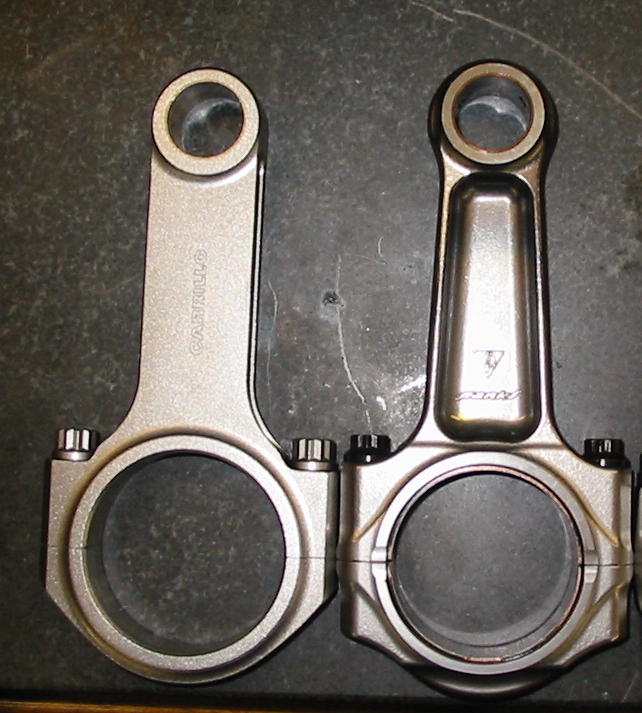

Here are examples of two different rods. The rod on the left is the “standard” Carrillo design and the one on the right is the stock Pankl GT3 rod.

In order to better compare, here is an example of another after market rod on the right, the Pankl rod is shown again in the center and the Performance Developments custom rod is on the left.

An engines displacement can also be increased by the stroke. It would make no sense to go smaller on the bore so we should only look at increasing the displacement from 3.6L and up. Based upon homologation requirements, the standard Porsche sizes have been the 3..8L bore only and the 4.0L bore and stroke. But you can build any size you require within the limits of the engines base architecture. The limit, as stated above on the stroke, is the oil pump clearance and the bore limit is the liner wall thickness. In building these GT3 engines the cost of changing any of these configurations is typically the same.

3.8L ( 3789.4cc ) 100.00mm x 80.40mm not a typical engine configuration

4.0L ( 3996.8cc ) 102.70mm x 80.40mm

4.2L ( 4209.8cc ) 105.40mm x 80.40mm

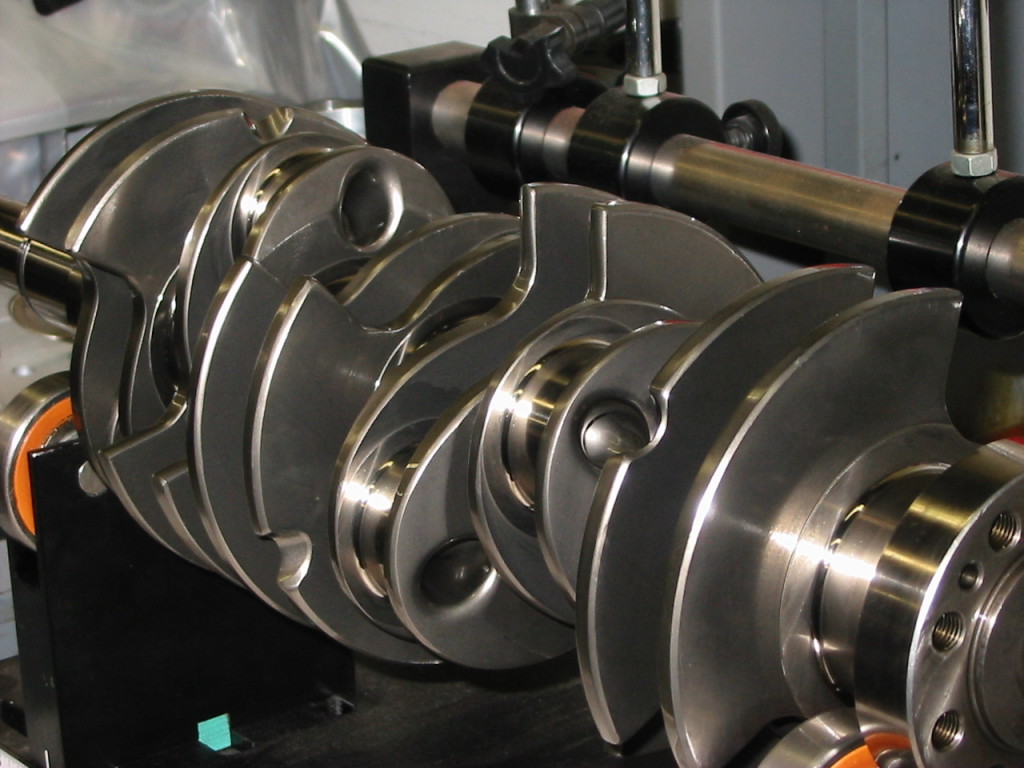

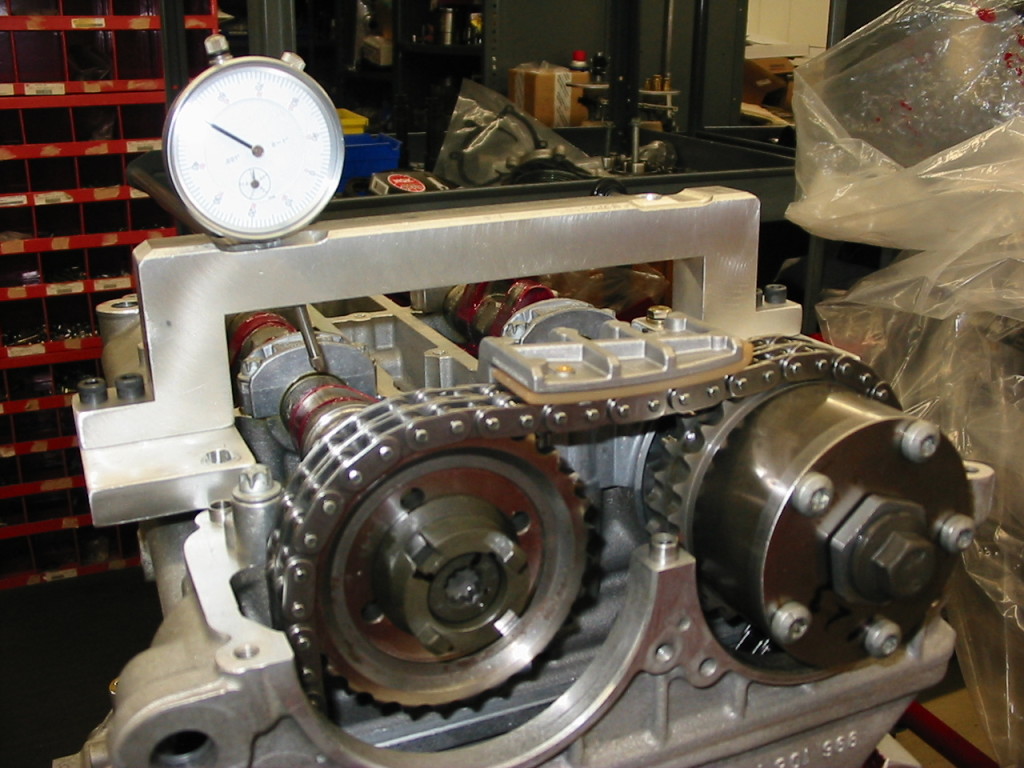

Stock GT3 Crankshaft

Performance Developments Crankshaft

The above sizes show how the engines displacement can be changed by stroke only. The 3.8L model is not one I would recommend, as adding the bigger bore always helps. The 4.0L engine can be built with bore and stroke changes, 102.70mm x 80.40mm or it can be done by bore only, 105.40mm is the common size. Seems a lot simpler to change the bore only but there are very big differences on how the engine will perform. It also requires certain machining operations to be done in order for the larger cylinders to fit. This is the part most customers do not understand or get told.

I’m often asked which way I would go. Well, if it’s a race engine I would always choose a bigger bore over stroke, but also note that in a race engine other engine parameters are also changed. Intake system, exhaust system, cams etc. Shorter crankshaft stroke will lower the losses caused by the piston rings (friction) and the piston travel is reduced per crankshaft revolution. Friction is increased exponentially with engine speed. This is why short stroke engines can typically run at higher engine speeds, more RPM, and more horsepower as long as the engine can continue to pump air.

Less crankshaft arm also lowers the amount of wind age caused by the crankshaft rotating in the engine case and lowers the piston speed. Piston speed accounts for most piston failures where the pins are pulled at extreme forces and often cause cracking in and around the pin bosses. These are extreme comments, but the theory is mentioned to give a full picture of the issues. The long stroke 4.0L engine with an 80.40mm stroke has an approx 24 m/sec piston speed which is acceptable with today’s technology, designs and materials used in piston manufacture. To put that in perspective, a F1 engine revving in the 20,000 RPM range has the same piston speed. In this engine, the shorter stroke lowers the piston speed.

In GT3 street engines, most often the displacement change is the only change. With all other engine parts being kept the same, which configuration makes the most torque? Both. Both will make the same or within 5 -10 Ft/Lbs. An insignificant amount when considering street engines. The intake system, cylinder head port volume, camshaft design and cam timing all will have a greater degree of effect on the overall torque number than any stroke change. In most street GT3 engine builds these parameters are not changed. Now, this changes everything and makes a difference.

It’s not just about size or the torque value, but more about useable torque within the use of the engine. Typically the longer stroke will promote the maximum torque at a lower RPM. For street use where the transmissions ratios are not changed and the use is from street light to street light, the longer stroke engine will be better. There are “buts” here also. For example, the re-tuning or mapping can make any engine, regardless of size or configuration, produce less performance. Friction, crankcase wind age and other parasitic losses can all contribute to lower engine performance. The highest friction level produced internally by an engine comes from the piston rings. This is why piston rings have become thinner in section and with new inner cylinder wall technology piston ring tension has dropped. This helps greatly when the surface area has increased with the bore increases. A lot of race engines run two rings only.

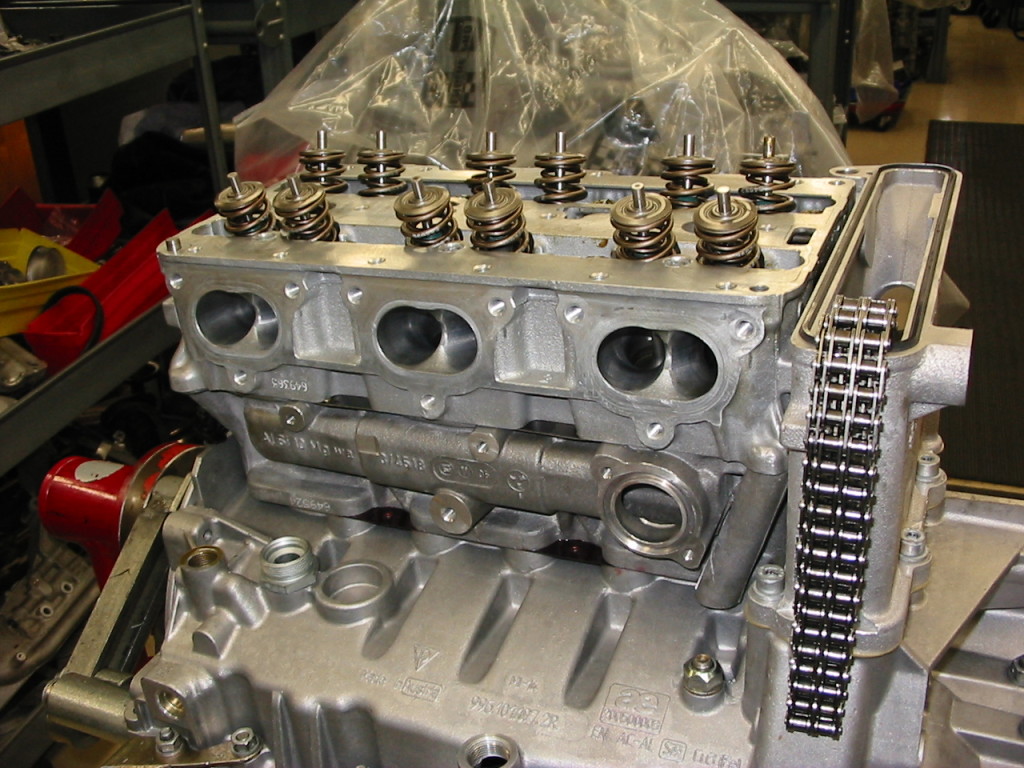

If you compare either engine of the same displacement, the long stroke small bore engine cannot match the short stroke big bore engine for efficiency. A bigger bore will always promote better breathing as the bigger bore allows bigger valves. Less valve shrouding, better airflow and a larger cylinder diameter giving more piston face area will increase the pressure exerted upon the piston. This increases the force put upon the connecting rod and finally the mechanical leverage on the crankshaft arm. So building a 3.8L small bore engine (100.00mm x 80.40mm) when you can build the same engine with a bigger bore is a much better choice. What about the choice of 105.40mm over 102.70mm bore sizes? Will the bigger bore size increase cylinder pressure and efficiency? The answer based upon our dyno testing is yes. However, the increase in stroke or arm length of the 80.40mm crank will trump the bigger bore for street and the occasional track driving. The longer mechanical advantage of the longer stroke will always win over the bigger bore, unless you address all of the other engine parameters. If you visualize the rod journal of the crankshaft at 90° to TDC a longer arm with have more mechanical advantage over a shorter arm. Although, as the RPM increases the frictional losses increase by the square, even though the engine with the longer stroke has a greater pumping ability. This is why the torque maximum is almost the same, but at a lower RPM.

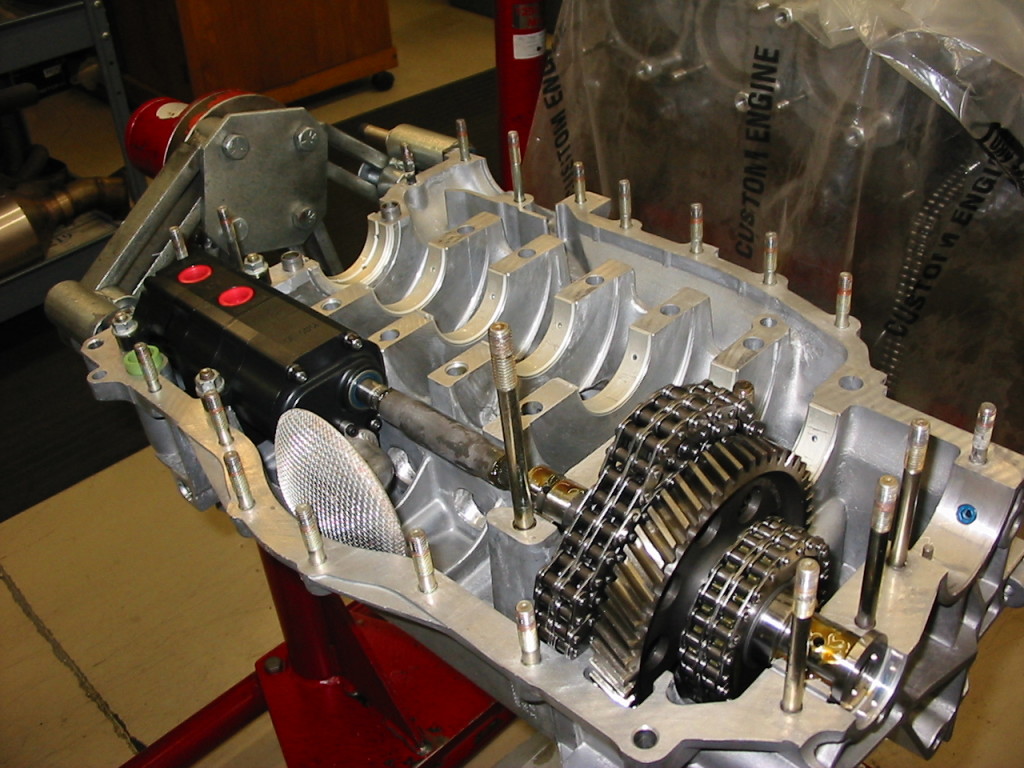

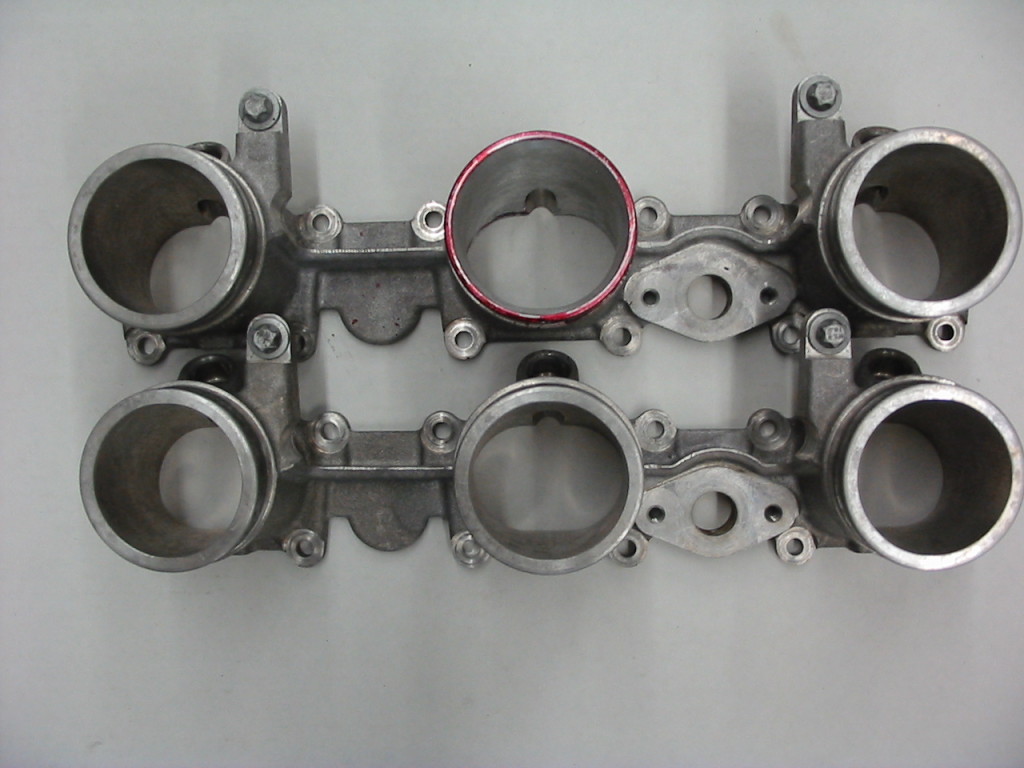

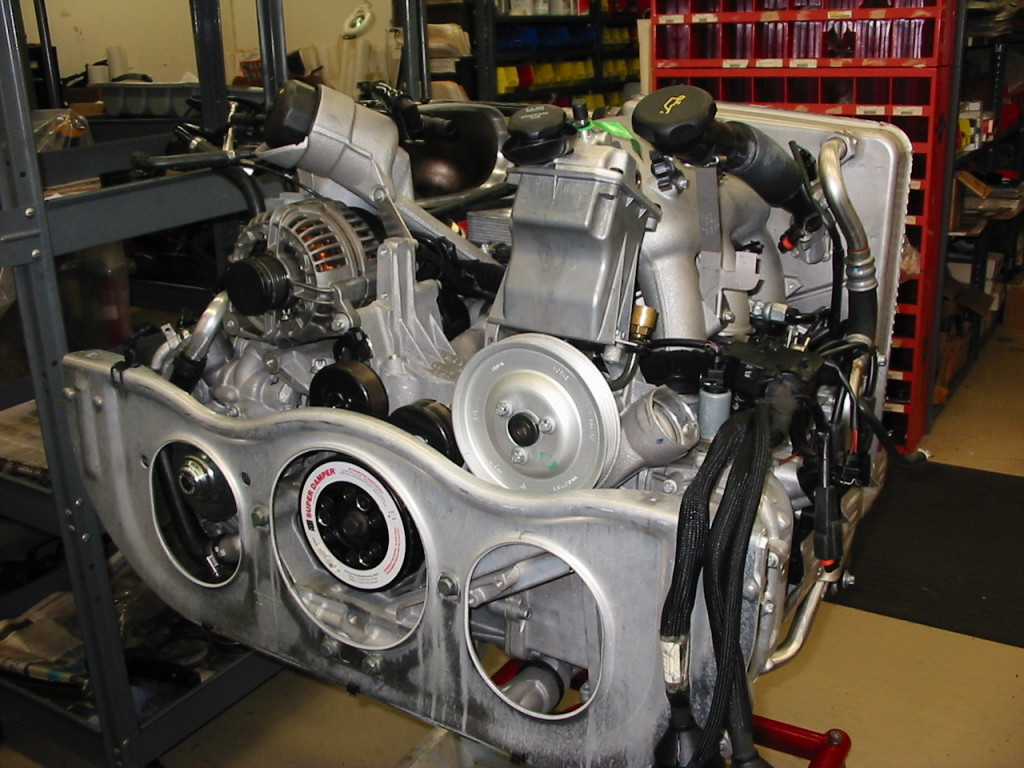

In most street GT3 engines the valves and other parts previously mentioned are not changed and the advantage of the bigger bore is diminished over the mechanical advantage of the longer stroke. It’s as simple as that. This is proven in the 4.2L (105.40mm x 80.40mm) engines. It does come down to the best of both worlds. In Performance Developments engines we increase both the valve sizes, camshaft profiles and timing, CNC port the lower manifold housings and fit the larger 4.0L intake manifold to aid better air flow. We do our best to overcome the frictional losses by making the pumping effect greater with more air volume and less restriction. It should also be noted that the camshaft or valve timing has a huge effect on the engine performance. With these engines Porsche has given us the ability to adjust the overlap (when both exhaust and intake valves are off their seats) which helps improve the low end response, mid range and upper RPM range. The GT3.1 engine has variable adjustment only on the intake cam and the GT3.2 engine has it on both. By increasing or decreasing the overlap period we can change the torque curve, take advantage of the larger displacement and the engines added pumping ability.

In normally aspirated engines the torque the engine can produce is directly related to the amount of air it can pump. As long as the engine can pump, and there are fewer or less restrictions for that air to pass by, the amount of air that is sucked into the cylinder will equate to an increase in cylinder pressure. More pressure increases the force placed upon the piston face and turns into rotating movement to the crankshaft and ultimately to the wheels. Increase the piston speed with a longer stroke and you lower the cylinder head ability to flow air versus engine speed. This is called the port choke. Another reason why the maximum torque is at a lower engine speed.

There are other factors to take into account too but it gets more complicated. A longer stroke will accelerate the piston faster away from TDC. This helps with the air being pulled through the intake system. The signal is stronger which, in turn, will increase the engines ability to respond to the fueling and ignition. It quite simply will make the engine more responsive given all other things being equal. The engines static compression ratio makes use of this by decreasing the volume above the piston which also increases the pressure upon the piston face. This is called the engines dynamic compression. If the average ignition timing on these engines is approx 26° BTDC the cylinder gases reach their maximum expansion level very soon after the ignition point. This becomes the “in cylinder pressure” which continues to rise until the crankshaft goes over TDC and the piston starts its downward decent. At approx 30° ATDC the “in cylinder pressure” has reached its peak and then decreases rapidly as the in cylinder volume increases with the piston travelling downwards and the rod angle increases towards 90°. Imagine the arm length as the crankshaft rotates. The rod angle increases with the longer stroke, thus, lowering the mechanical advantage or pressure pushing on the crankshaft arm (torque).

Now add in a longer or shorter connecting rod. What difference do these make? First off let’s look at some basics. The distance between the crankshaft centerline and the piston deck face is a constant. For street GT3 engines it is typically approx 190.00mm. So when you have a fixed dimension adding stroke shortens this dimension. In the case of the 80.40mm stroke it shortens it by 2.0mm over the stock stroke. 2 up and 2 down. So either the stock rod or stock piston have to change their basic dimensions. Typically it’s the piston. The compression height of the piston, or the distance from the pin centerline to the top of the piston, is decreased by this same amount taking into consideration any piston deck height required. So nothing else really changes. Basically, the piston speed increases with stroke but the piston behaves very similarly with the shorter stroke as the rod length remains the same.

Connecting rods typically sold in the after market are copies of the stock rod. Big end and small end bore sizes, big end and small end thickness, along with center to center lengths all remain the same. In most cases the rod manufacturer has a “standard” design or forging and the big end and small end radiuses are set. This is often not a good fit and don’t lend themselves to situations where internal clearances become an important issue. In some cases the rod center to center length is shortened to meet the new installed dimension by the rod manufacturer as the “tuner” relies upon the rod manufacturer to do the engineering for them. It’s the easiest part to change. Now the rod angles become very acute and the mechanical advantage becomes even less. The characteristics of short connecting rods are explained in more detail later.

So what if we increase the rod length as well? In Performance Developments 4.0L and 4.2L GT3 engines our rod is longer than the stock rod, even after adding an additional 4.0mm to the crankshaft stroke (see previous photos of rods). This requires the piston pin to move up even further, often into the oil ring groove. This is common and quite normal today.

A long rod engine will decelerate the piston as it gets closer to TDC and dwell at TDC longer. For the same reason the long stroke engine will place more stress on the rotating parts, the longer rod will help straighten out the rod and lower the forces acting upon the rod and piston. The long stroke engine will always increase the piston speed and decrease the time the piston has to change direction. It will put more stress upon the piston requiring the piston to be designed accordingly. As stroke increases the piston has to travel further per unit of time or engine revolution. However, the longer rod will slow down the piston velocity countering some of the increases the stroke creates. It reduces wear on the walls of the cylinder and the skirts of the pistons. It also helps the engines ability to lower the tendency to detonate. This allows us to run a slightly higher static compression which makes the engine more responsive. The longer stroke and longer rod combination help pull the air through the intake system harder for a longer crankshaft rotation that helps make the stock intake a little more efficient as engine speed increases. With the variable cam timing control (VVT) we can change the valve overlap period to take full advantage of the longer rod. The downside is the piston speed across BDC increase making the movement of the piston or change of direction a little harder and adds more stress. Good design and well made parts can handle these forces and the rod reciprocating weight, the piston weight including the pin, clips and ring weights. It’s these changes in direction at TDC and BDC that cause the failures in most engine bottom ends. The engines ability to raise the G loading as the engine speed increases allows for higher engine speed to be used.

A short rod engine will be the opposite of the long rod. It will give the piston a higher velocity, will increase the rod angle and put more force on the piston skirts and cylinder walls. As the piston reaches TDC it will spend less time there and lower the engines ability to reach the same cylinder pressure. This time or less of it spent at TDC will require more ignition timing to be used as the time for the flame propagation is less and volume above the piston will decrease quicker over the same time and crankshaft rotation. It does slow down when the piston goes through BDC but the most stress put upon the piston is as it changes direction over TDC. The engine tries to pull the pistons out through the top of the engine with the G forces produced.

There are a lot of other factors involved here also, too many to list without going into further detail. But these are the factors we take into account when designing a configuration and the choices you can have. It costs no more to add bore. The cost of cylinders and pistons are almost the same regardless of diameter. Stroke does cost more, but the returns for a street engine with some track use are huge.

If you feel you want a track only engine, go with the big bore but don’t forget about the intake and head flow along with camshaft configuration. If you are a street driver who sometimes tracks the car, go with the stroke. Most drivers are not at a pro level and heavy on the brakes which drops the engine speed through and out of the corners. You need the low end torque to get the car accelerating back up to speed.

So, to sum up, what’s the best configuration? Our dyno testing has shown that the 4.0L long stroke long rod engine is better suited for most street and track use over the big bore engine. If you can afford to, do both. But remember as bore goes up so does weight and weight plays a huge part in an engines life and RPM potential. Well designed and well made parts are essential and there lies a lot of the differences available to customers of these engines. Remember, these engines have an inherent low engine RPM harmonic. Performance Developments designed the GT3.1 balancer to counter this and will soon release the balancer for the GT3.2 engine. Whatever is done to your engine, engine safety must still be number one priority and the builders underlying consideration.

I tell customers this simple calculation. Compromise less on the engine and your disappointment level will be compromised less but your wallet will be compromised more. Compromise more on the engine and your disappointment level will be compromised more and your wallet less.

You have choices. You can have an engine built just to your needs. Don’t settle for “off the shelf” parts unless you are prepared to compromise the performance. It is your choice.