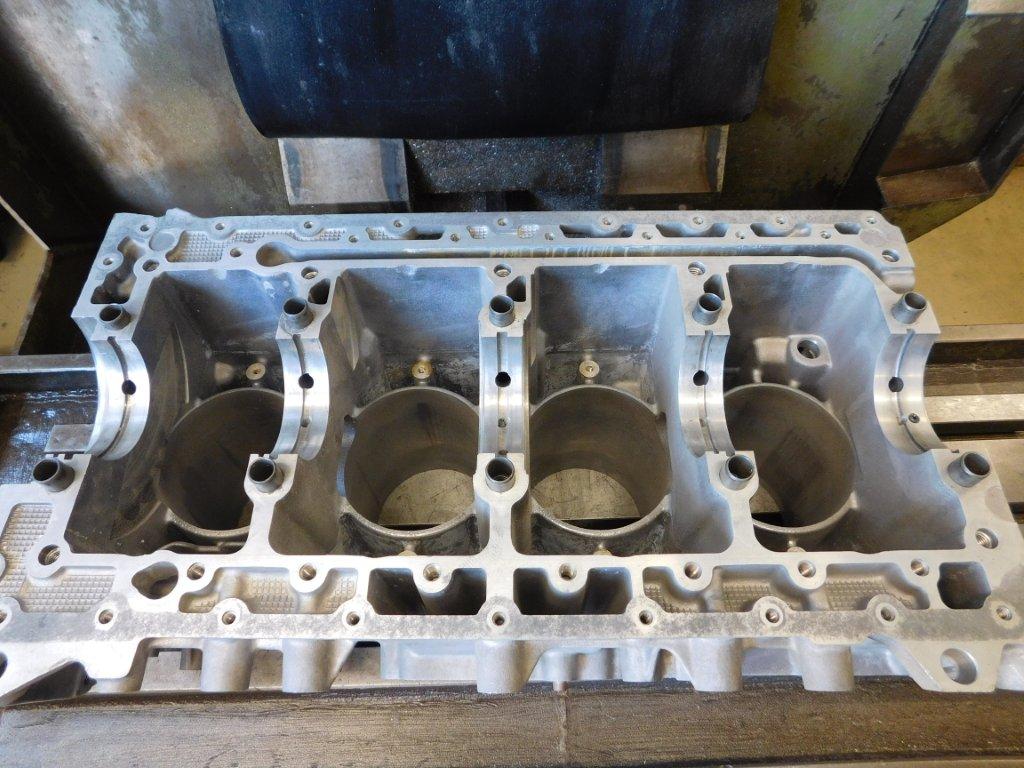

Porsche 944-968 Engine Block Lower Member Upgrade

This part is typically known as the girdle. It houses the lower bearing shells and holds the crankshaft in place.

This part is located to the block upper portion with 12.00mm studs on each side of the main housing bore, 8.0mm and 6.0mm bolts attaching the girdle to the block upper around the pan rails.

Unlike many domestic V8 and V6 engines that double up on the main studs (4 bolt mains) or splayed attachments, these blocks use only one stud to secure the girdle. The girdle is located at the rear main with 2 dowels and at the front by the single fully round main bearing shell. If you look closely the block and girdle are drilled for a locating dowel but it is never installed.

We install a dowel 12.00mm stud to each side of the main housing bore on each main web. This locates the girdle securely with the upper block, holds the block and girdle from deflecting under load and keeps the main bearings from distorting when the girdle deflects and twist under load.

These two images show the tooling we use to locate the girdle so the main housing bore stays in alignment during the machining procedure.

If you install the girdle without the front main bearing you can see the amount of movement the girdle can be put under, especially at the front main. All of this is held in place by the front main. The bore holes in the girdle are larger than the studs, so the girdle can flex at each main due to its lightweight design.

If we hold the girdle in check at each main, then the bearing shells will not be placed under load and deflect. These bearings will have approx. 0.0015- 0.0035 overall clearance to the crankshaft journal. One half of that clearance is all the girdle needs to flex for the bearing to lose its clearance and touch the crankshaft journal.

These two images show how the machining process is done with the alignment bar installed and the girdle fitted.

Maintaining the correct oil clearance here is also critical as the rod journals are fed directly from the main journals. Any loss of oil clearance and oil volume at the main will affect the oil supply to the rod journal.

With the girdle attached to the upper block section and the movement of the girdle and block main webs minimized, stiffens the whole block assembly. The greatest load placed upon the lower portion of the block is the rotation of the crankshaft. The front or nose of the crank does most of the movement as the torsional twisting caused by the torque pulses has its greatest effect on the lightest part of the crankshaft assembly. These cranks typically weigh in at approx. 54 lbs., so there are huge forces involved at 6000+ RPM.

These two images show the dowels installed in the block.

Call or email for further information about this upgrade.