Porsche 944 and 968 Crankshaft Upgrades

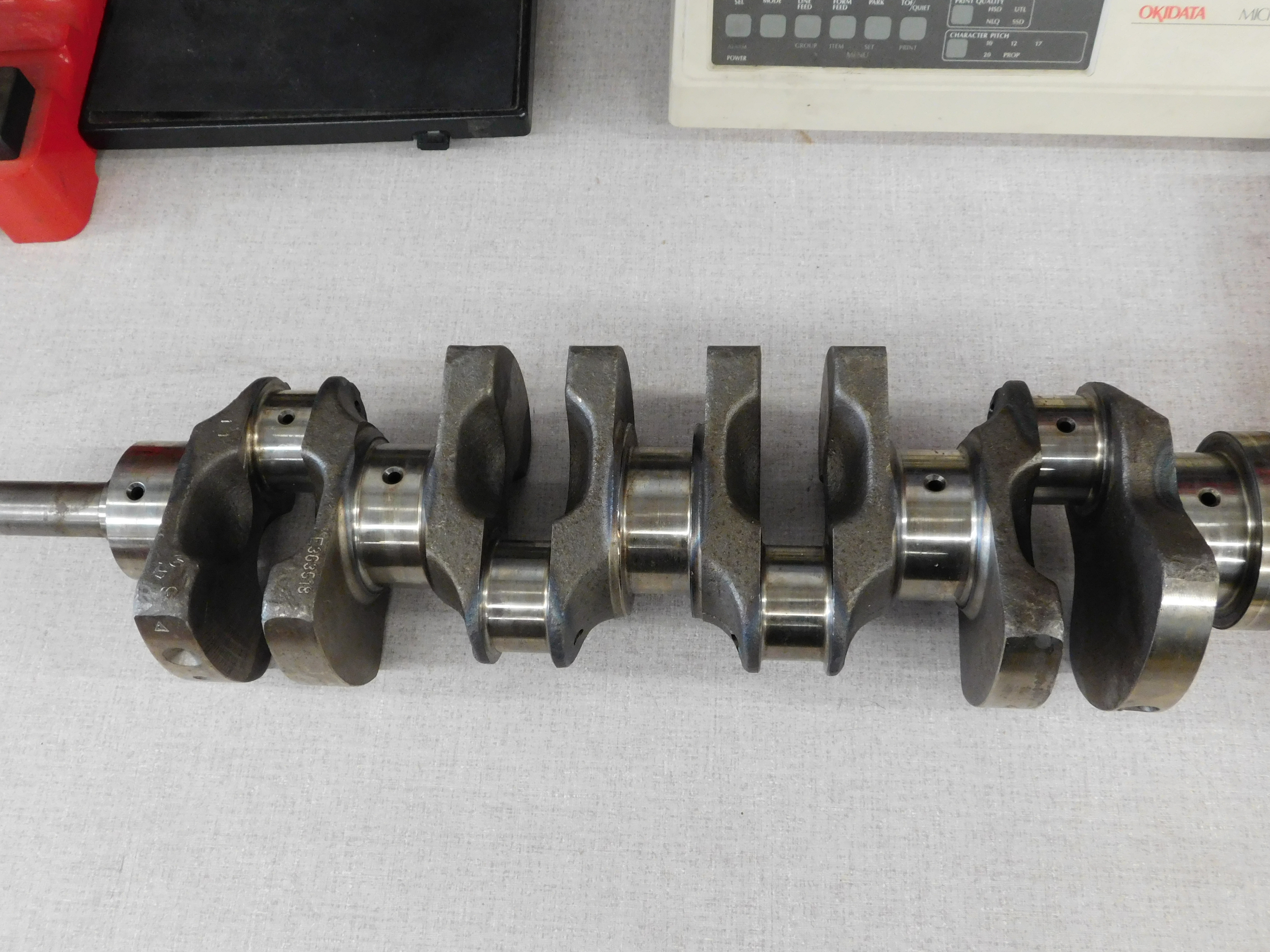

These are extremely heavy crankshafts in stock form. The stock crank weighs approx. 54 lbs. This is more than some crankshafts for engines with more cylinders. For any sort of performance engine, anytime you can shed some rotating weight it is a good thing.

However, taking weight out of a crankshaft needs to be done carefully and at the correct place. Knife edging is a common practice, but one that should only be considered when the full consequences are understood. There is no oil laying in the bottom of the oil pan for the crankshaft to slice through when the engine is running. All the oil is stacked up against the wall of the block and pan from centrifugal force created by the rotation of the crankshaft.

Dynamically these engines have 1st and 2nd order imbalance issues. Therefore, balance shafts are included. These engines suffer a rocking motion front to back which is caused by the pistons change of direction, the differences in piston speed from TDC to mid stroke and mid stroke to BDC. Add to this, the imbalance is doubled because two pistons are traveling in the same direction at the same time through the same crankshaft rotation.

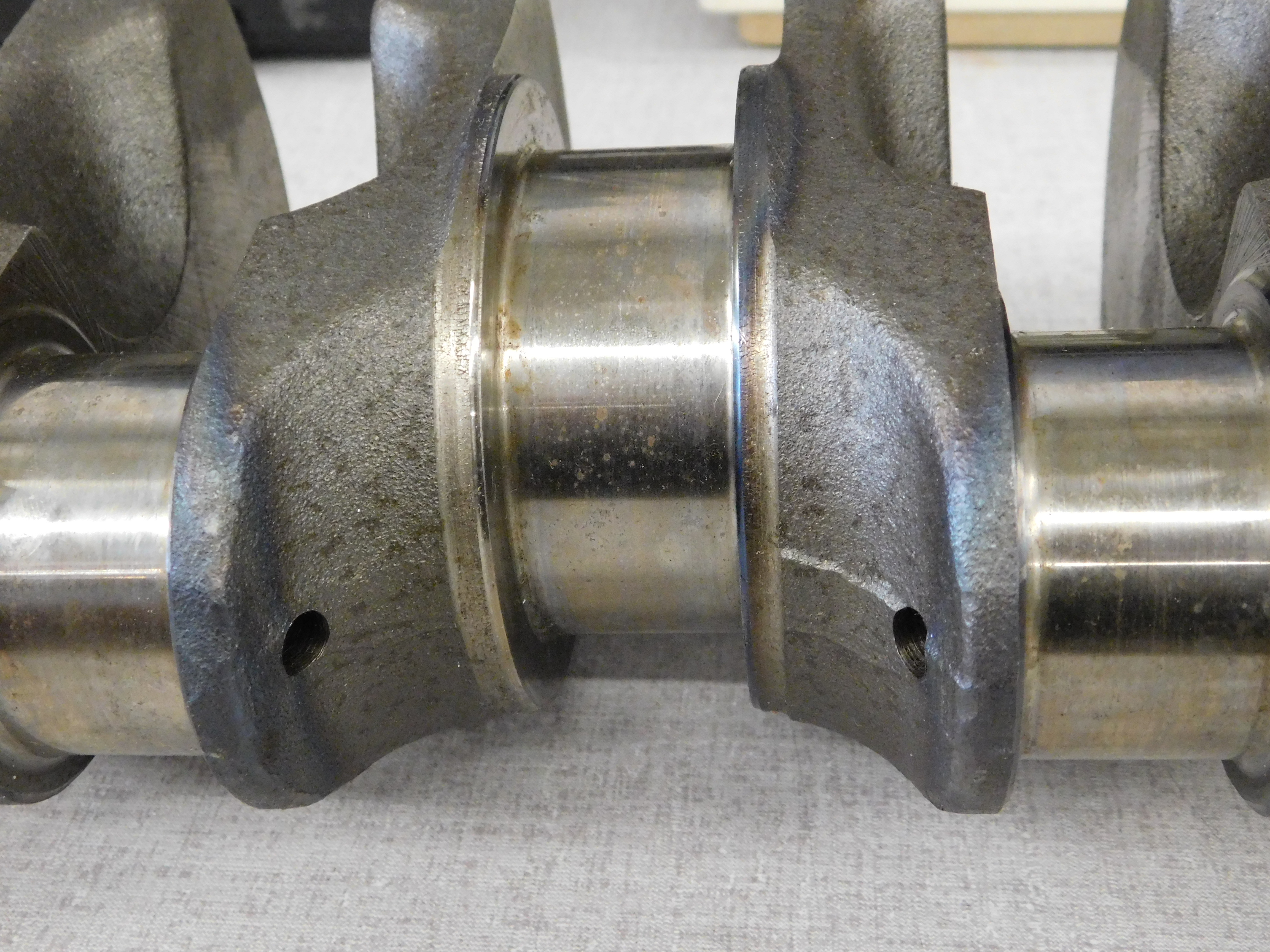

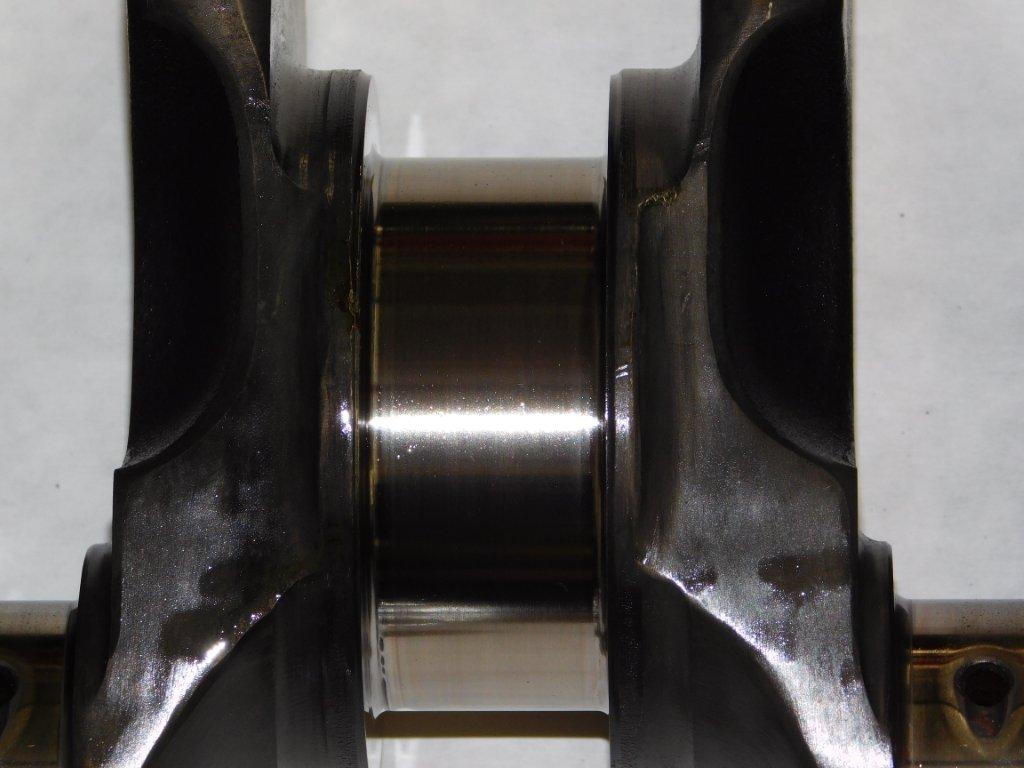

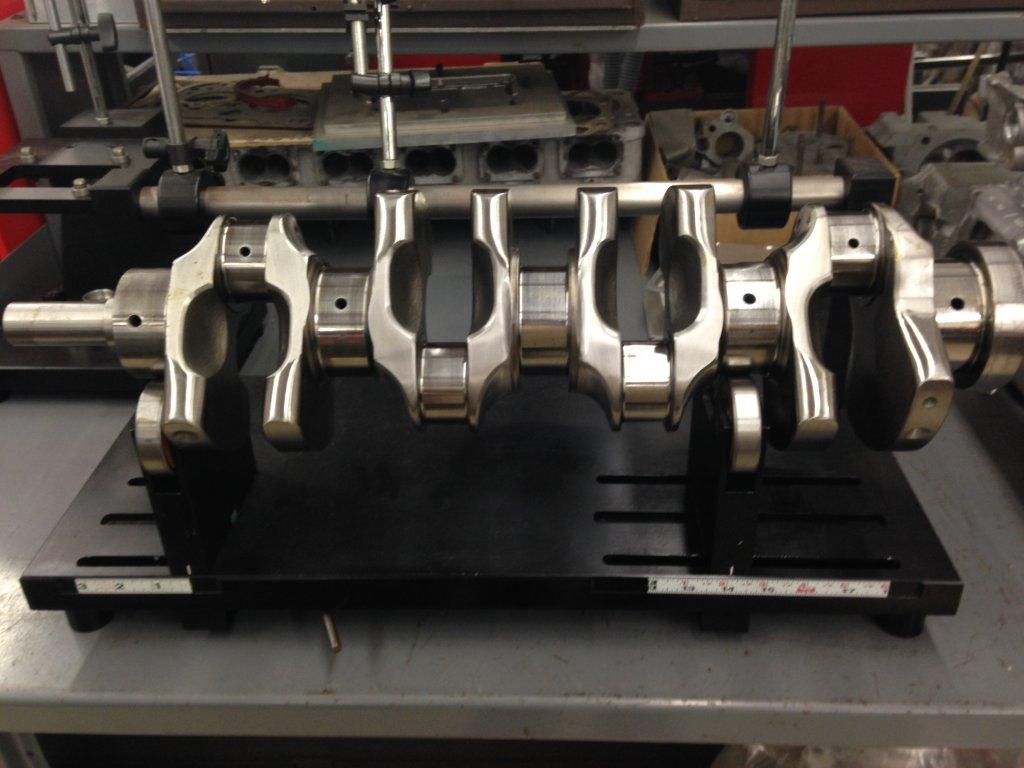

For aerodynamic reasons, the counterweights are bull nosed to help the counterweights travel through the thick oily air trapped in the oil pan without removing any mass. We also remove some of the mass that is at each side of each crank and at the crankshaft center. By removing some weight at the crank, it slightly increases the percentage of counterweight, helping with the engines balance. Any slight reduction in weight has huge advantage as engine speed increases. Removing weight out of the crankshaft is always a good thing, but it must be done correctly as any advantage from weight reduction can be wasted with increased harmonic issues.

Torsionally, these engines suffer the same twisting affects all other engines do. To help with this, balance shafts are added to help cancel out the harmonic forces created by torque pulses induced from the firing of each cylinder under compression. Keeping the crankshaft as straight as possible and limiting the amount of back and forth twisting is the job of the counterweights and the balance shafts. We are aware of the importance of these parts, so any modifications we do are based upon the safety of the engine. The vibrations created with the high intensity twisting of the crankshaft travel up the timing belt into the camshaft and play havoc on controlling the valve train. As soon as the cam timing becomes erratic, performance loses are increased. Typically, you are unaware that you have lost performance as the engine appears to be normal.

Anytime you can lower the parasitic loses from rotational weight, lower the inertia mass that must turn through 360° and weight that effects the friction loading, helps recover performance loses that do not have to be produced by hot rod parts. Engine acceleration is often misinterpreted as the torque the engine produces. The engine has a peak torque limit at a certain engine speed where friction and other loses overcome the engines ability to do “work”. If you can accelerate the engine quicker to this limit, the cars performance will increase even if the torque value does not.

The photo’s here show a stock crank as a comparison to our modified crankshaft.