Porsche 962c Race Engine: Part 1

The engine hours are at the limit for what we run these engines to, so it is time for a complete rebuild. When these engines were raced professionally the limit on an engine was 30 hours. Often the rebuild would happen before 30 hours if the next race would take the engine past 30 hours. These engines were very expensive to rebuild, as some of the parts were extremely expensive. The cylinder heads were more than $6000.00 each and you needed 6. There are some other areas of this engine that were troublesome and needed regular attention. The gear drives between the 1st motion shaft and the cams was a part that required careful attention, otherwise a major engine failure would occur.

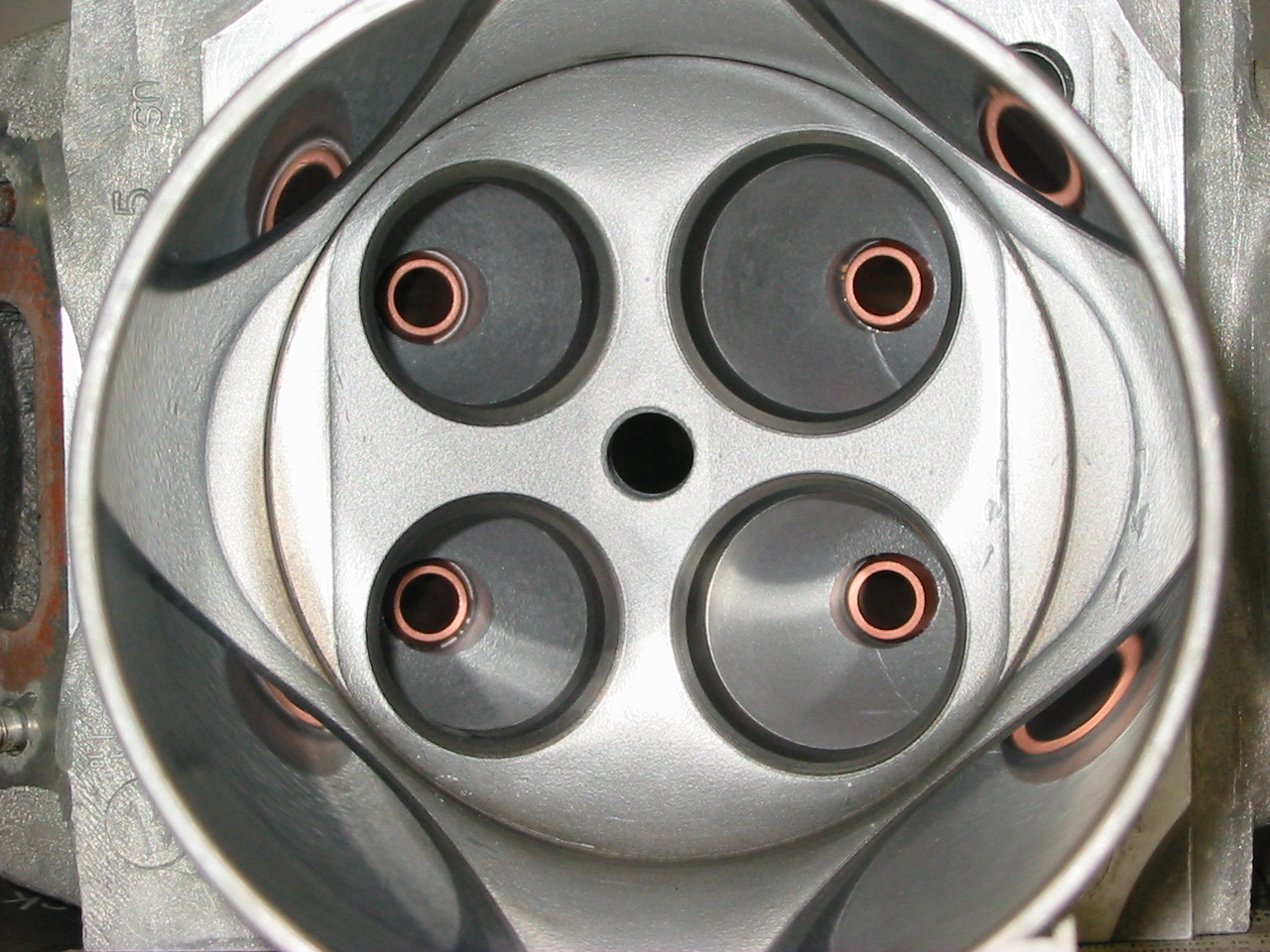

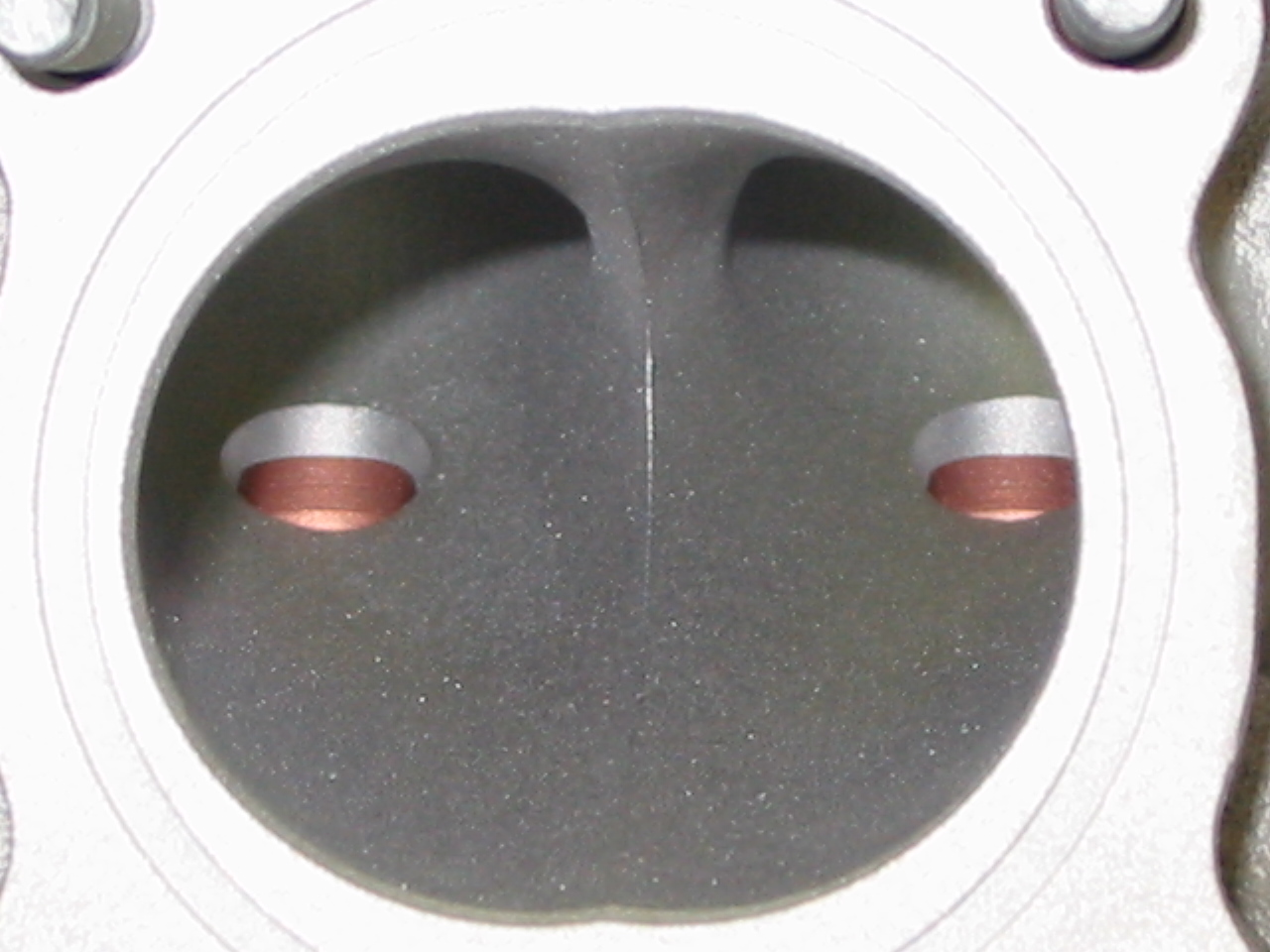

We developed many alternatives that allowed the heads to be reused, made the valve seat refurbishment a lot easier and our modification to the gear drive parts made these parts serviceable.

The following photos show some of the changes we made that lowered the rebuild costs and made the engines more reliable.

The engines are shipped in metal crates that protect the engines in transit. We try to remove the intake system and some other parts as the engine is unpacked so we can blow off the dirt and other debris before being brought into the shop.

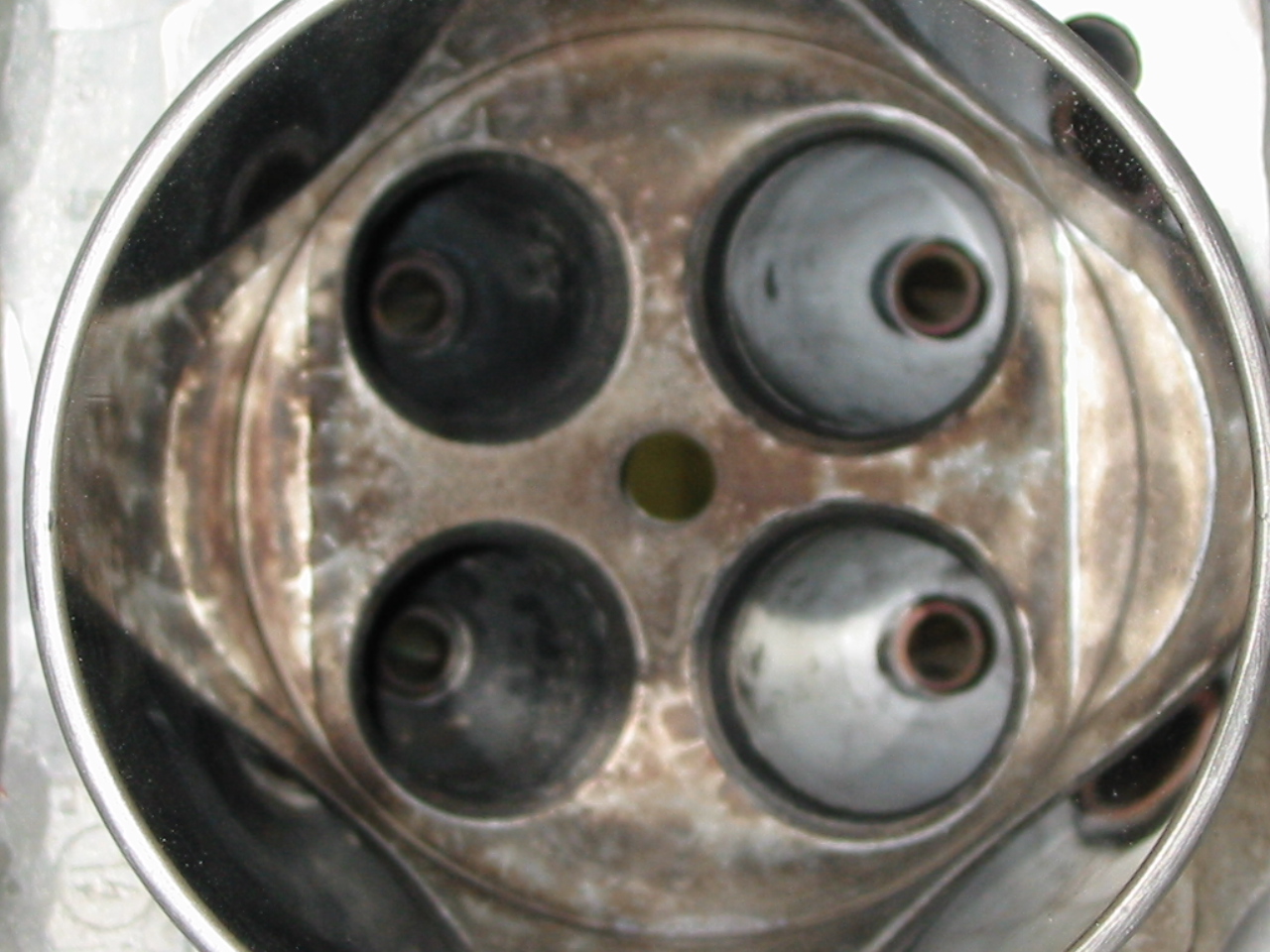

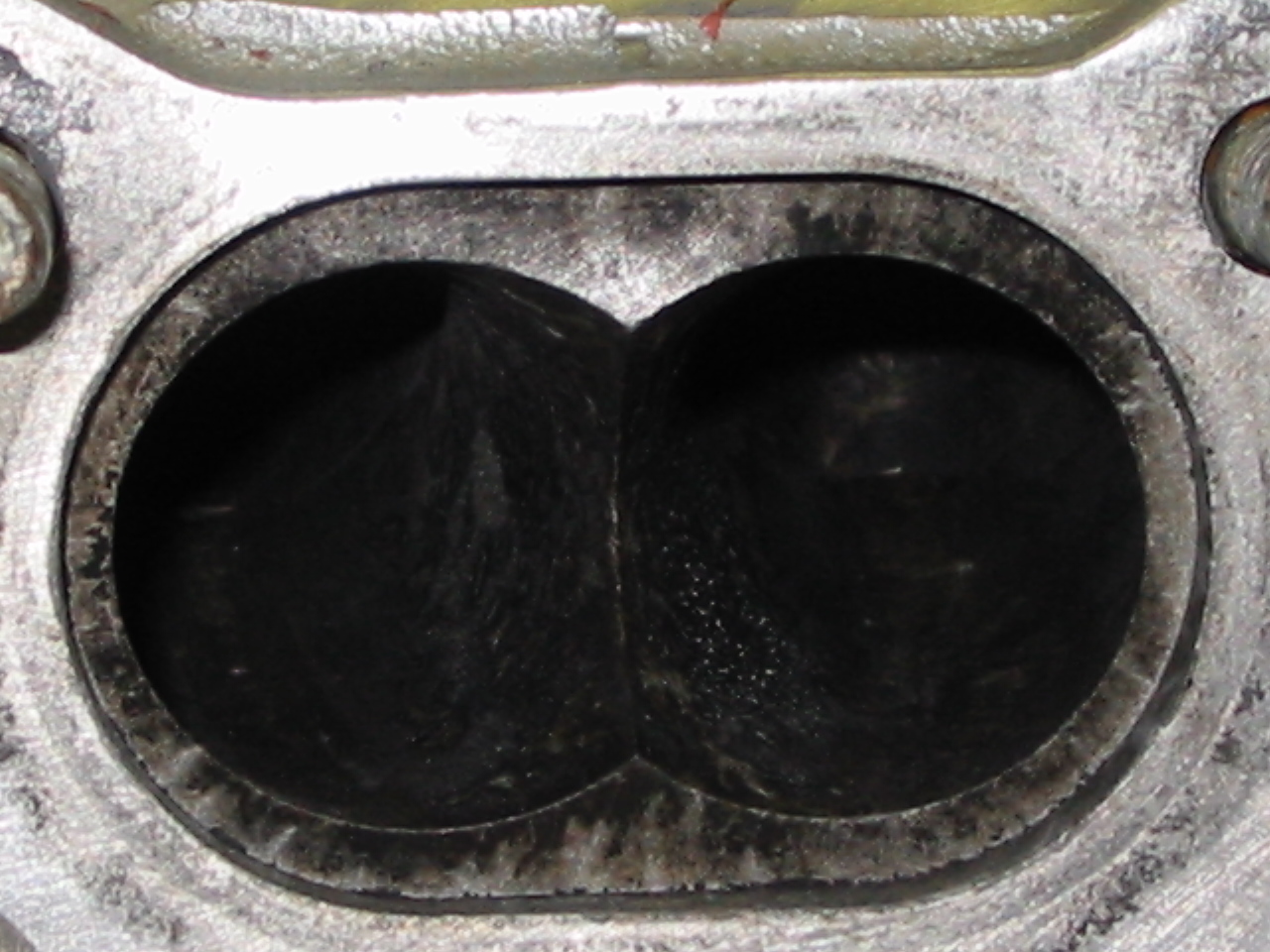

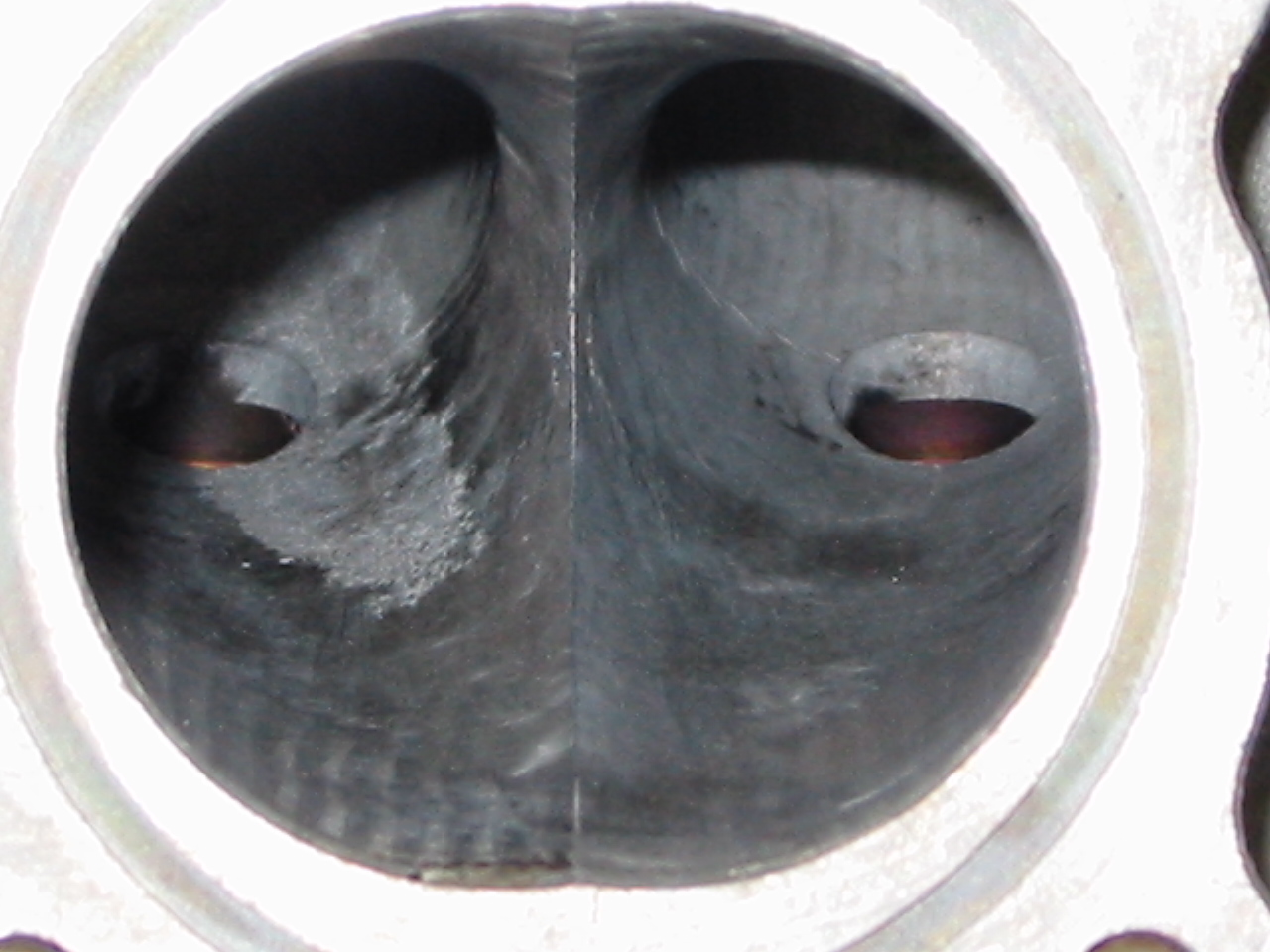

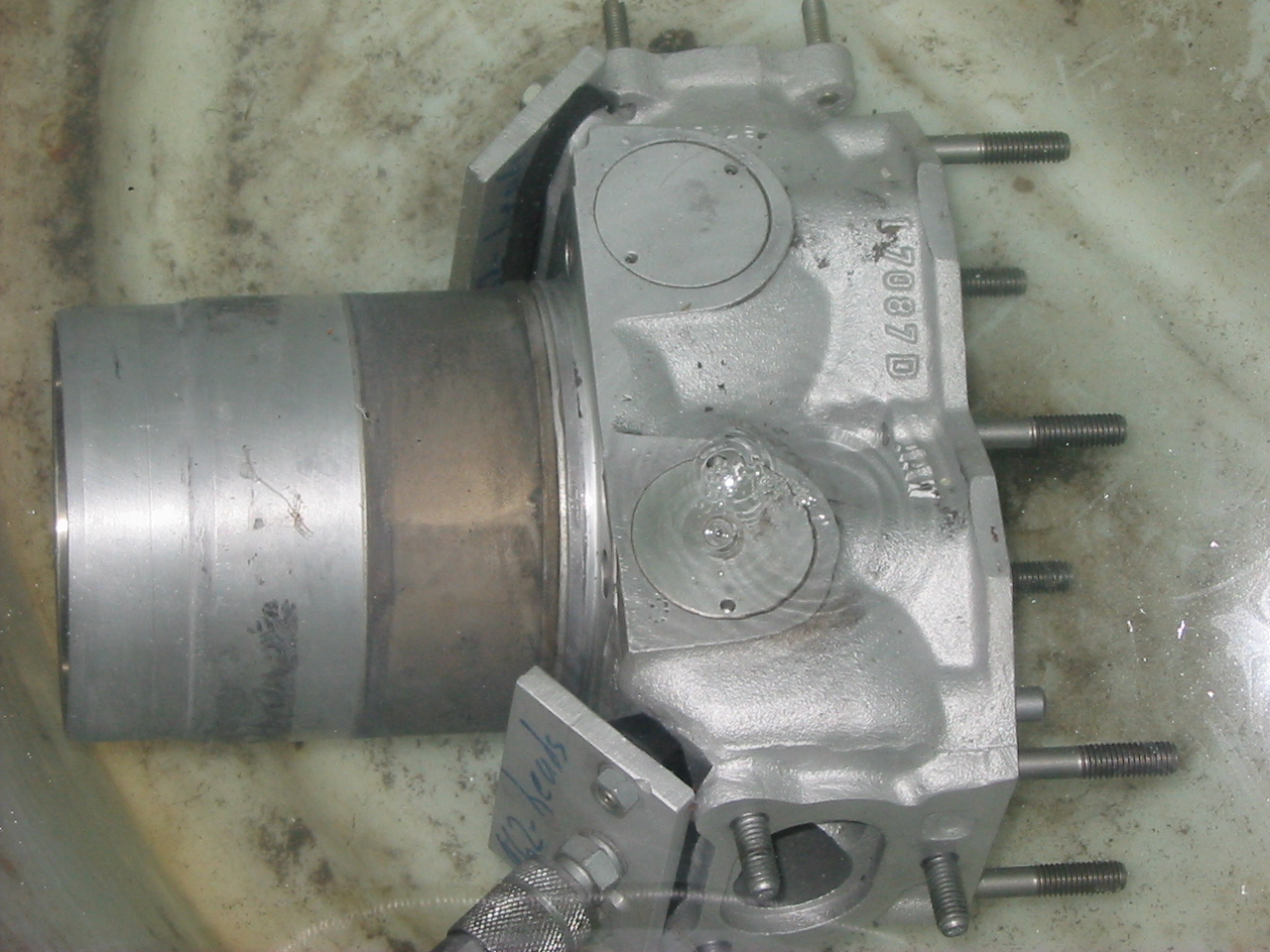

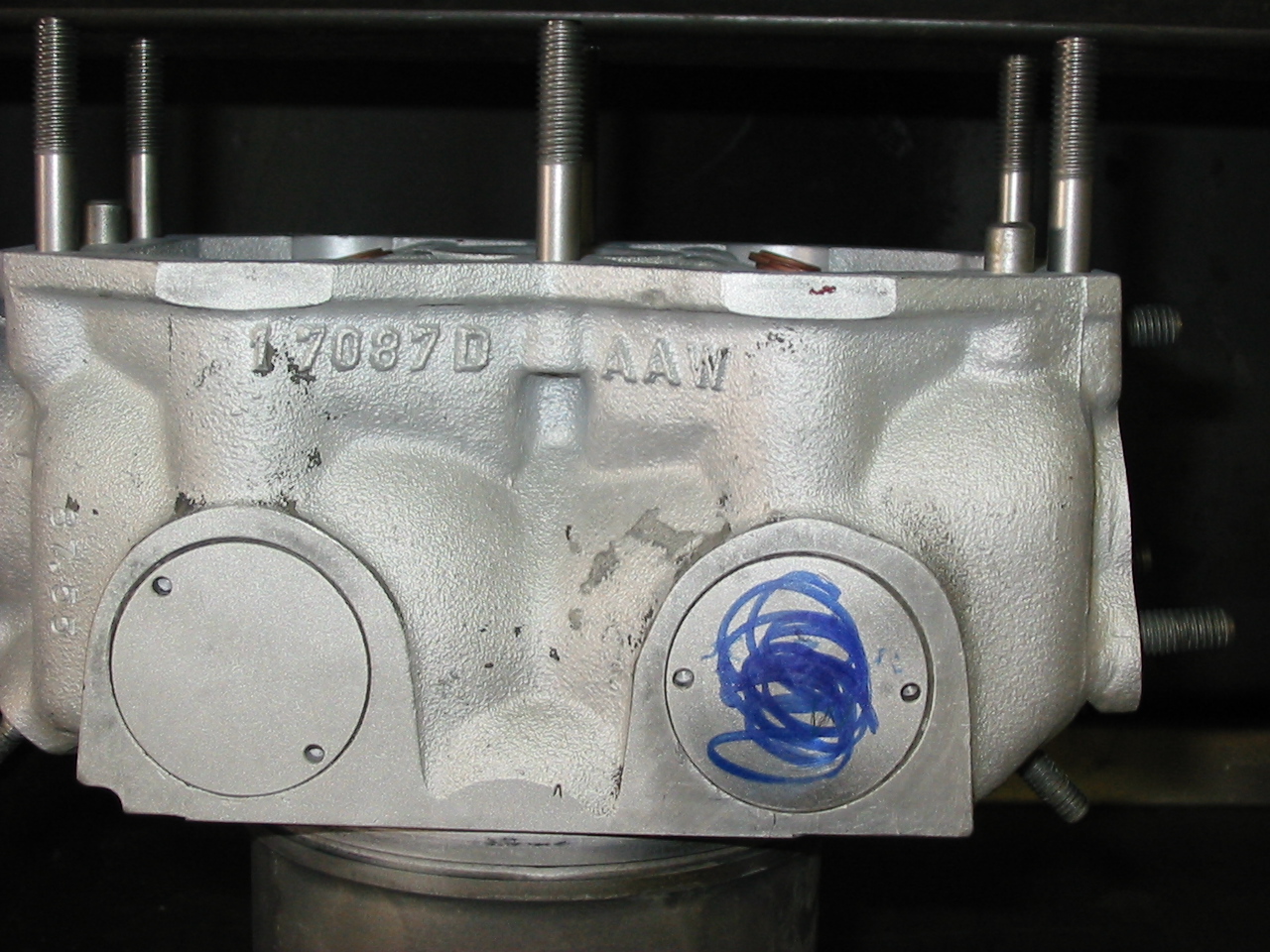

The engine is completely disassembled and every part thoroughly checked including non-destructive testing (magnufluxing and zyglow crack checks). Cylinder heads are pressure checked and casting plugs removed if any show signs of leaking.

Pressure checking heads.

Leaks found on some casting plugs. These will be removed, cleaned and re sealed.

All parts are cleaned and hot power washed and go through an ultrasonic cycle to be absolutely clean before crack checking is performed.