Porsche 962c Race Engine: Part 3

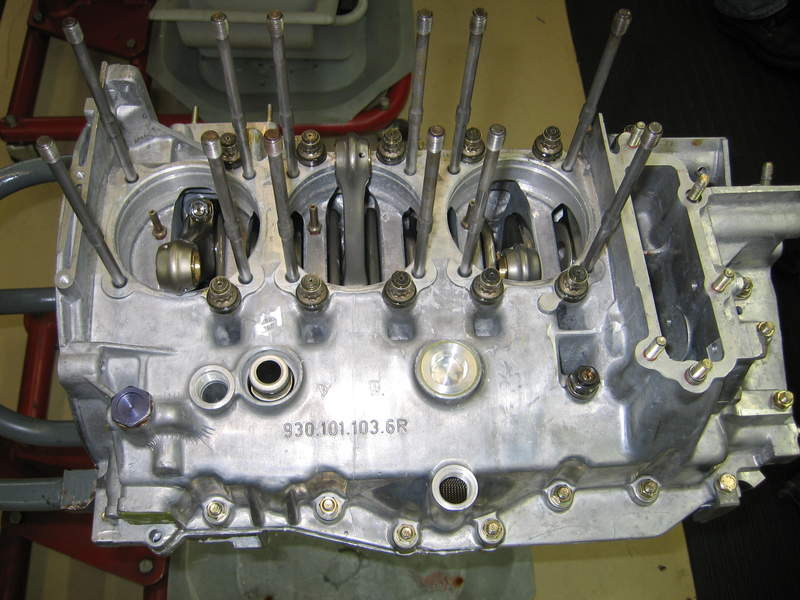

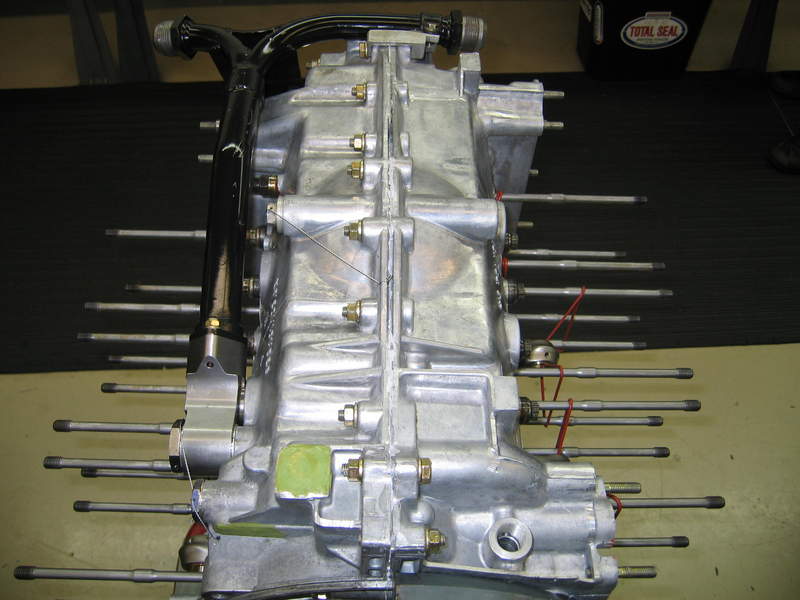

The crank case goes together very similarly to any other 911 engine. The oil pump is a multi-stage scavenge pump with two pickups. One forward and the other in the same position as the modern GT3 pump. Through bolts are bigger in diameter than street engines and the middle sections acts as a dowel at the case parting line. Photos show the 2nd scavenge outlet, banjo assembly for the oil out and the pipe that runs to the oil coolers.

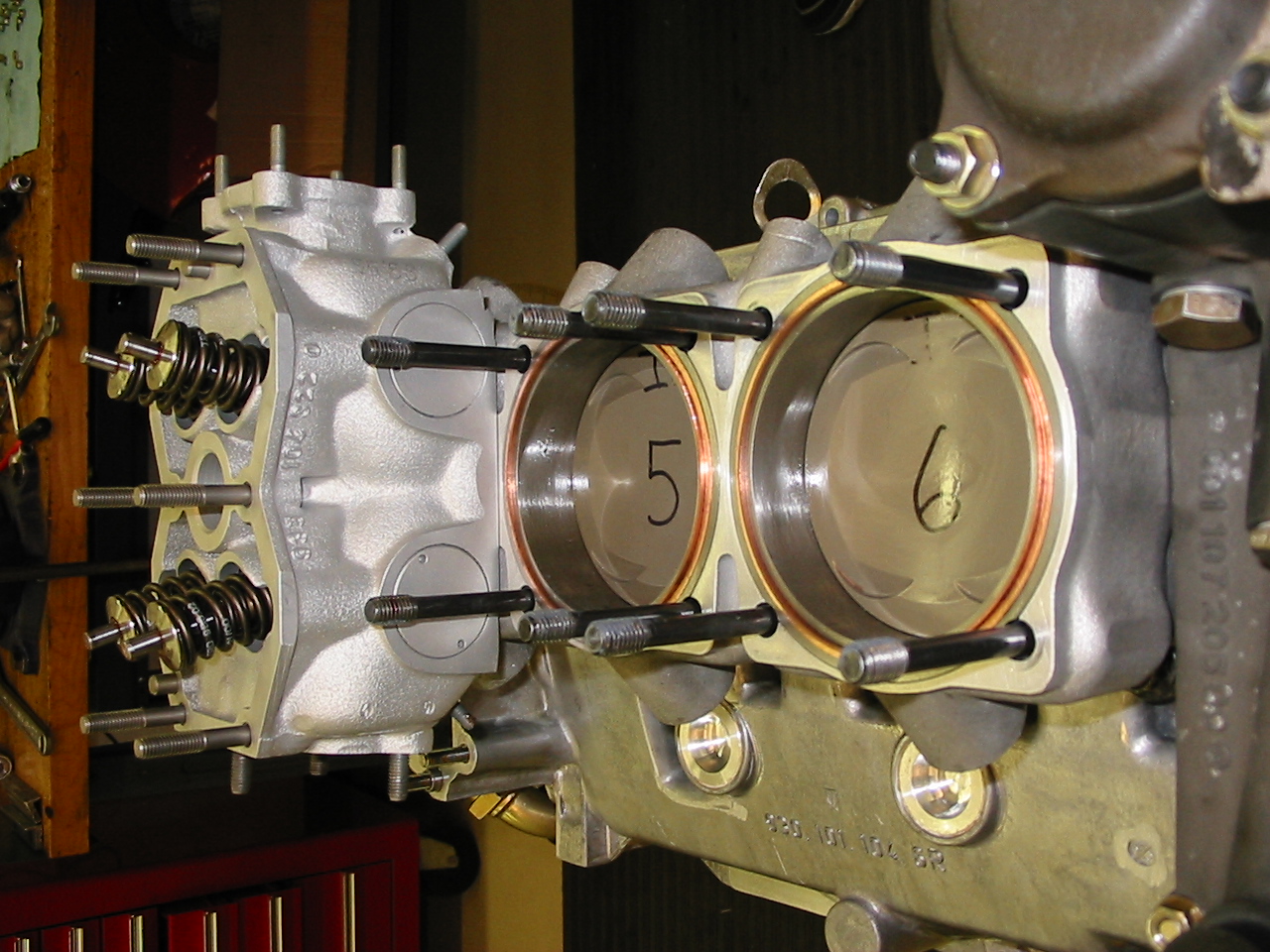

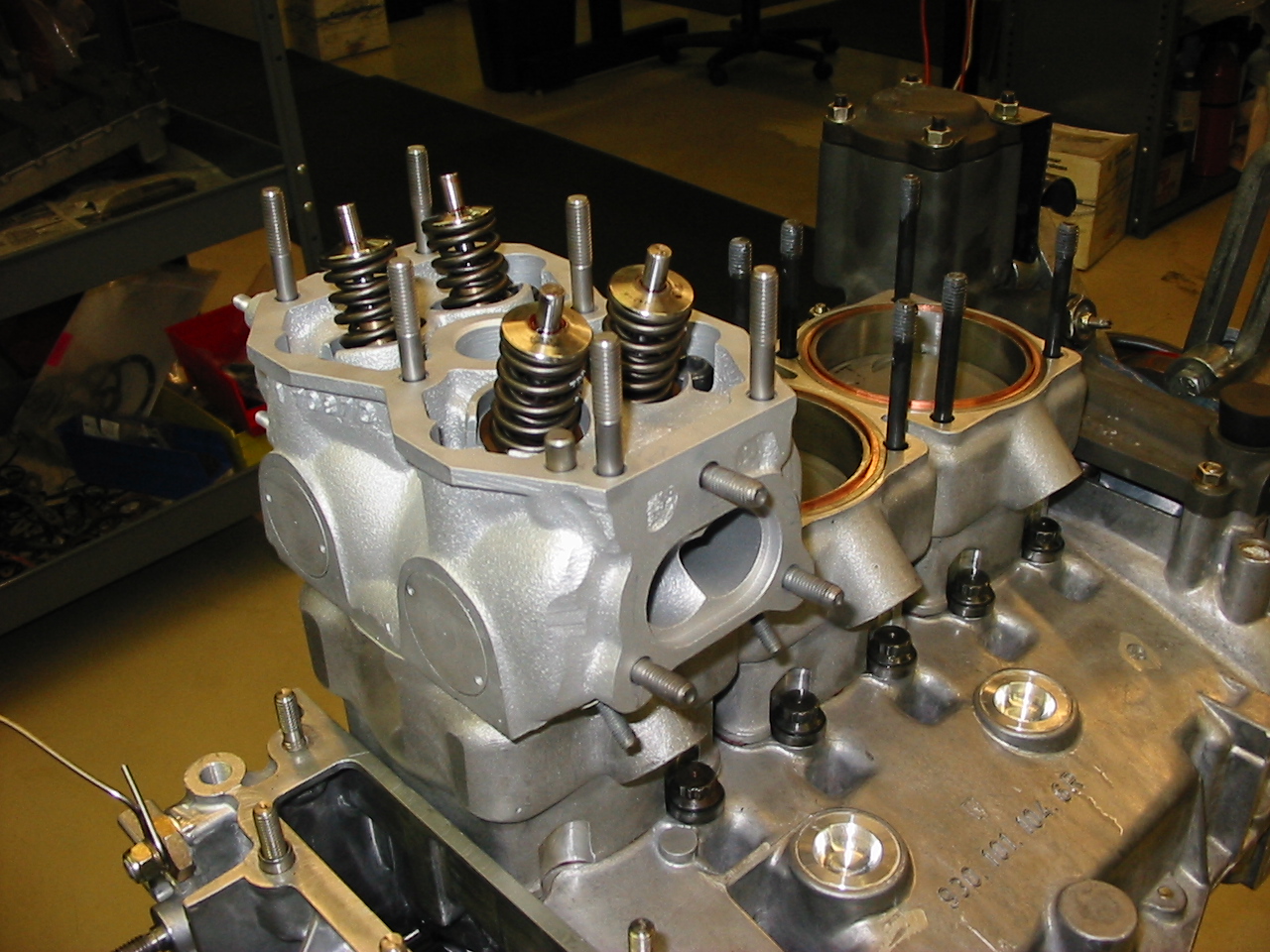

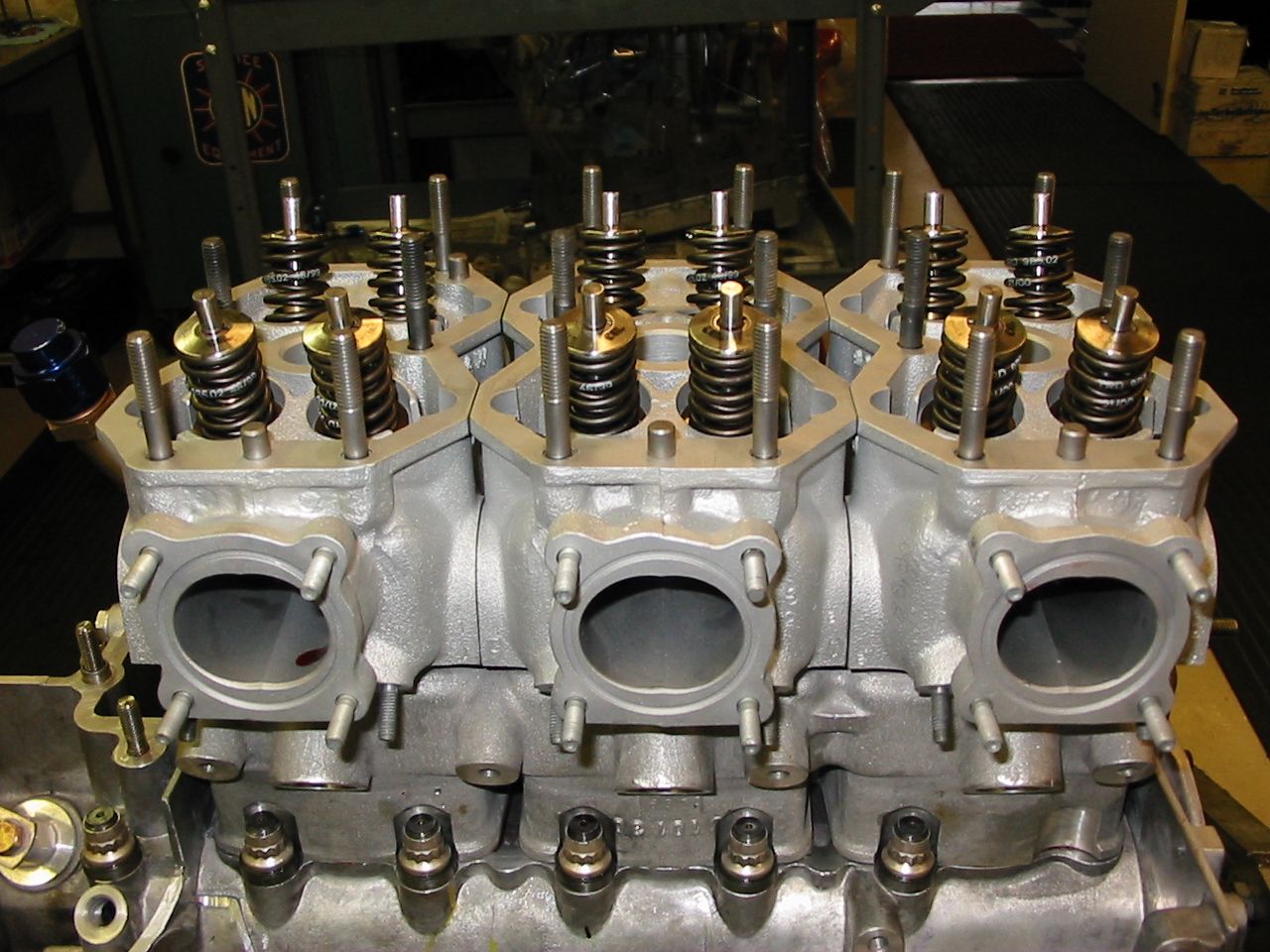

Pistons are oil cooled with a lower cavity under the crown. We remove the liner section from the cylinder heads and run a separate liner. We did this back in the early 90’s, something Porsche has followed with the later water cooled engines. This also makes repairing the valve seats a lot easier. Shown is the sealing gaskets we use. These are the same used on all 911 street heads to stop combustion gas leakage. Photos show the head assemblies being fitted.

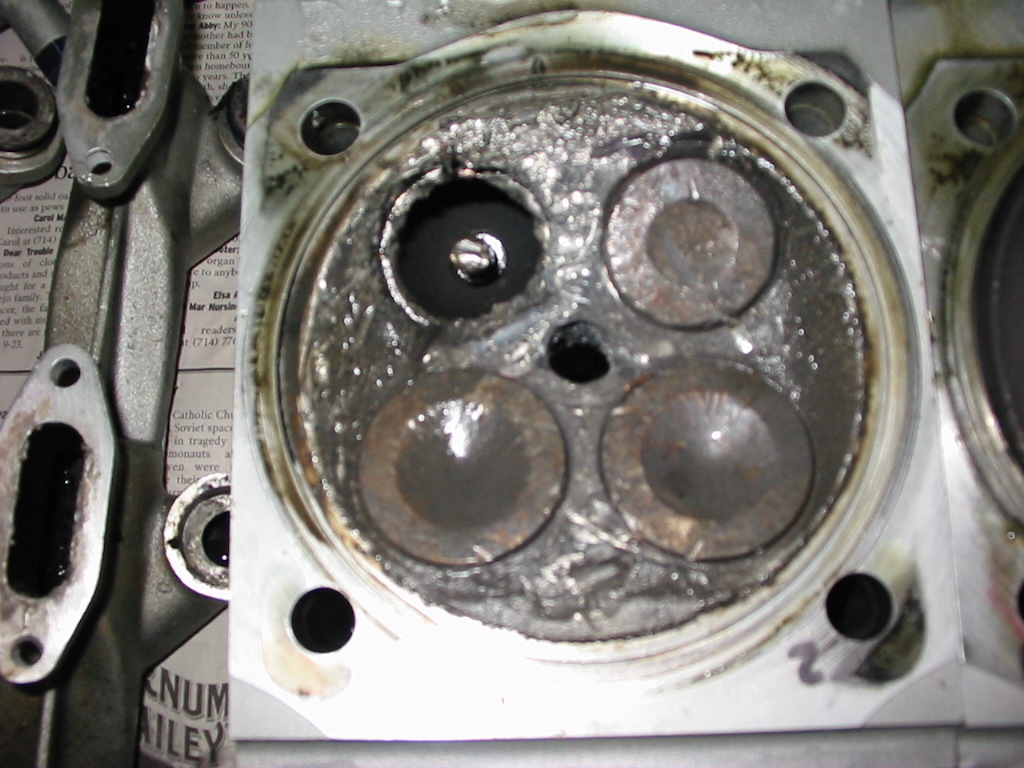

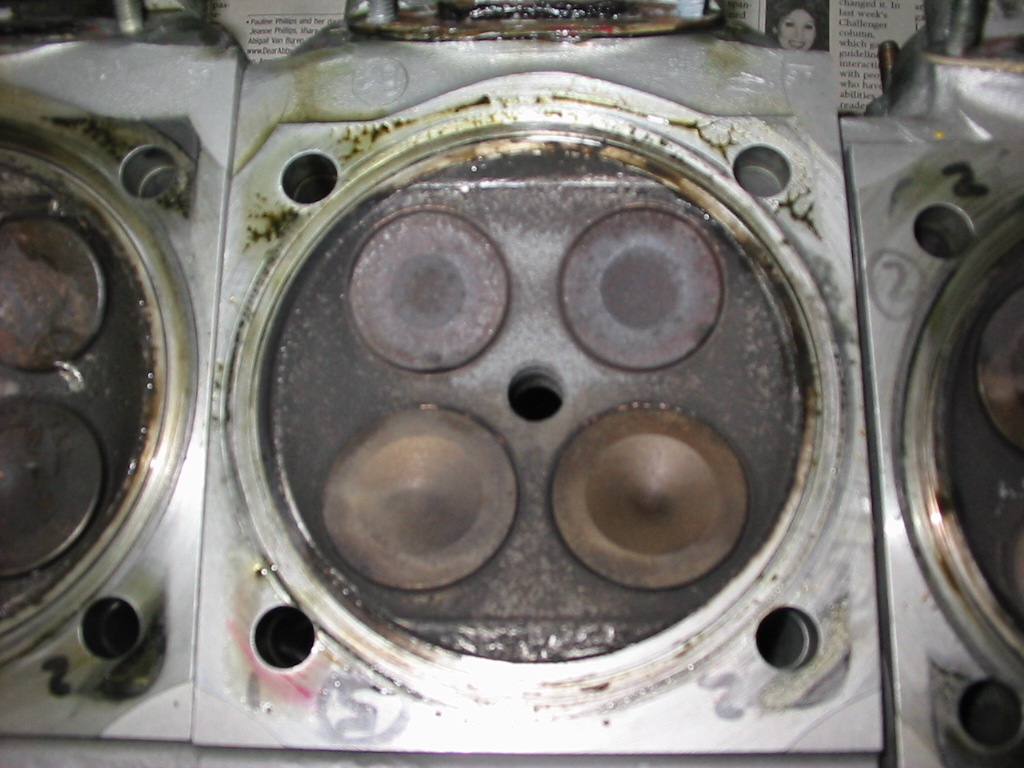

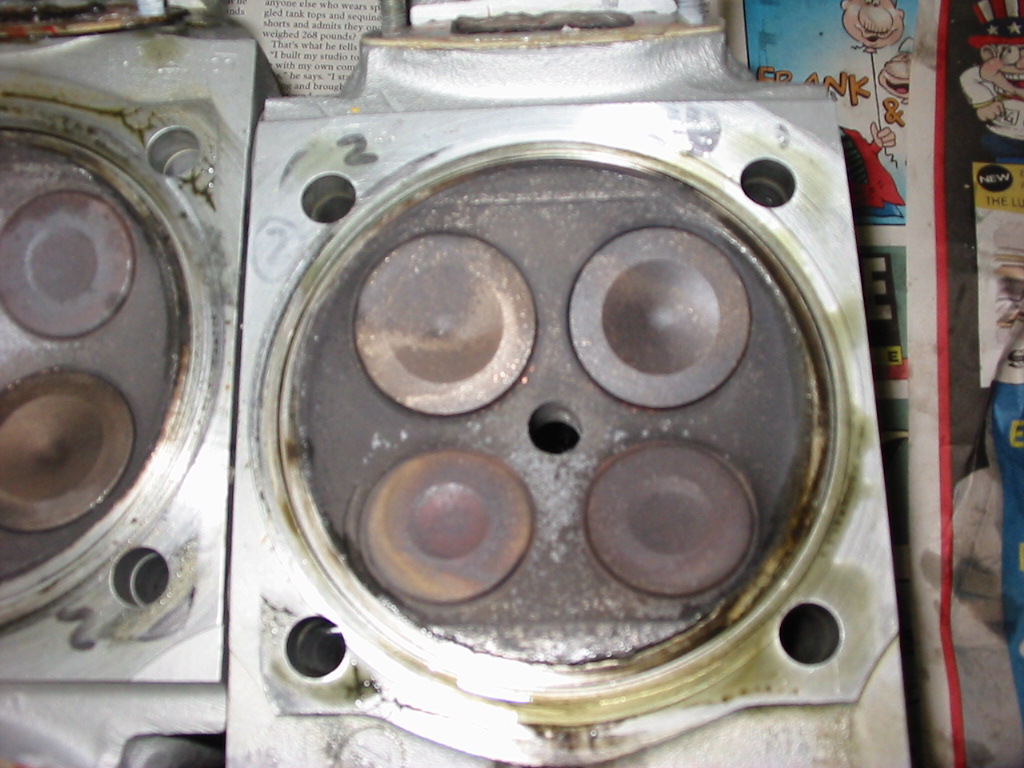

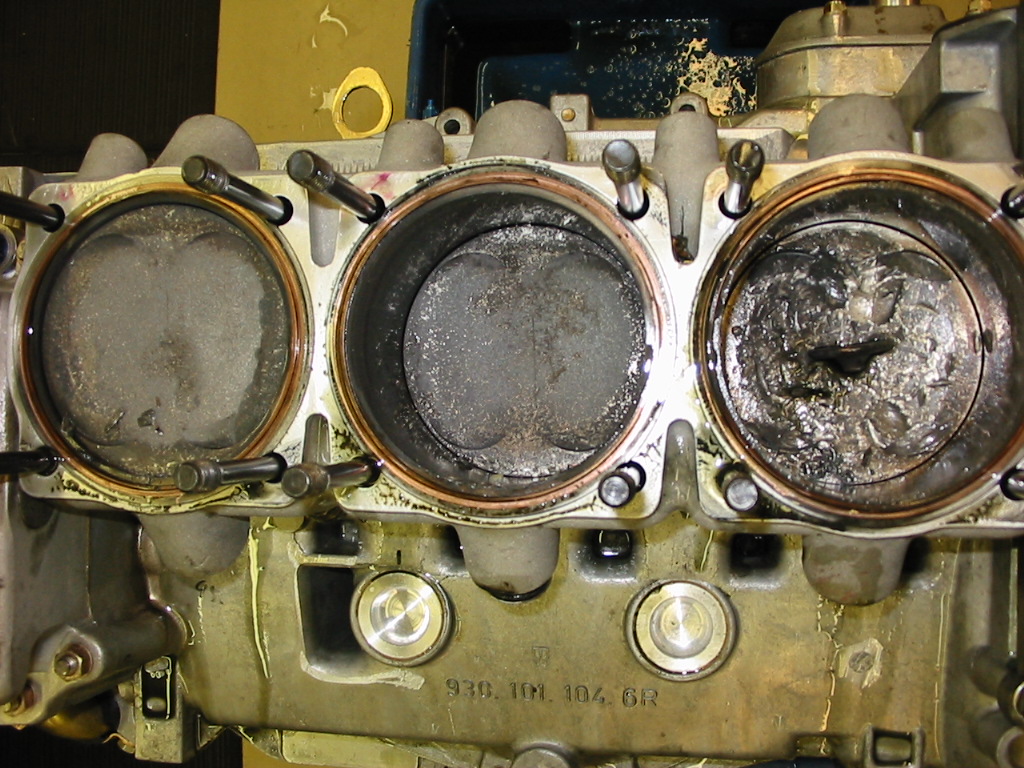

Here are some photos of what happens when you run past the rebuild hours. Valves were not replaced when they should have been and reused in a fresh rebuild. Valve head separated from stem and the resulting damage can be seen. We get the hard stuff, the stuff to fix when it all goes wrong.