Air cooled Cylinder Head Sealing System

One of the common problems with the Porsche 911 air cooled engine is the head sealing. After some time, many start to show signs of leaking between the cylinders and the base of the head. Especially on the exhaust side, you often can see an oily mess at the parting line.

Many of these engines have no sealing between the two parts, other than a contact surface. Upon disassembly both surfaces show signs of pitting and wear. When the heads are rebuilt, a surfacing operation is usually required.

Some of these engines have sealing rings, but still rely upon the two surfaces mating up to one another.

When we first got involved in rebuilding these engines in the late 1980’s we saw the need to seal up the two parts of these engines and use a gasket system that acted as a head gasket between the two parts. Some of the early 911 Turbo engines used a stainless fire ring between the cylinder and the head. This ring was not very good at sealing the two parts as it was primarily there to stop the flame travel from burning its way out. This primitive system also did not stop the head from banging against the cylinder top. Our system uses some interference between the sealing gaskets and the head and cylinder. This interference compensates for any head lift due to pressure and temperature.

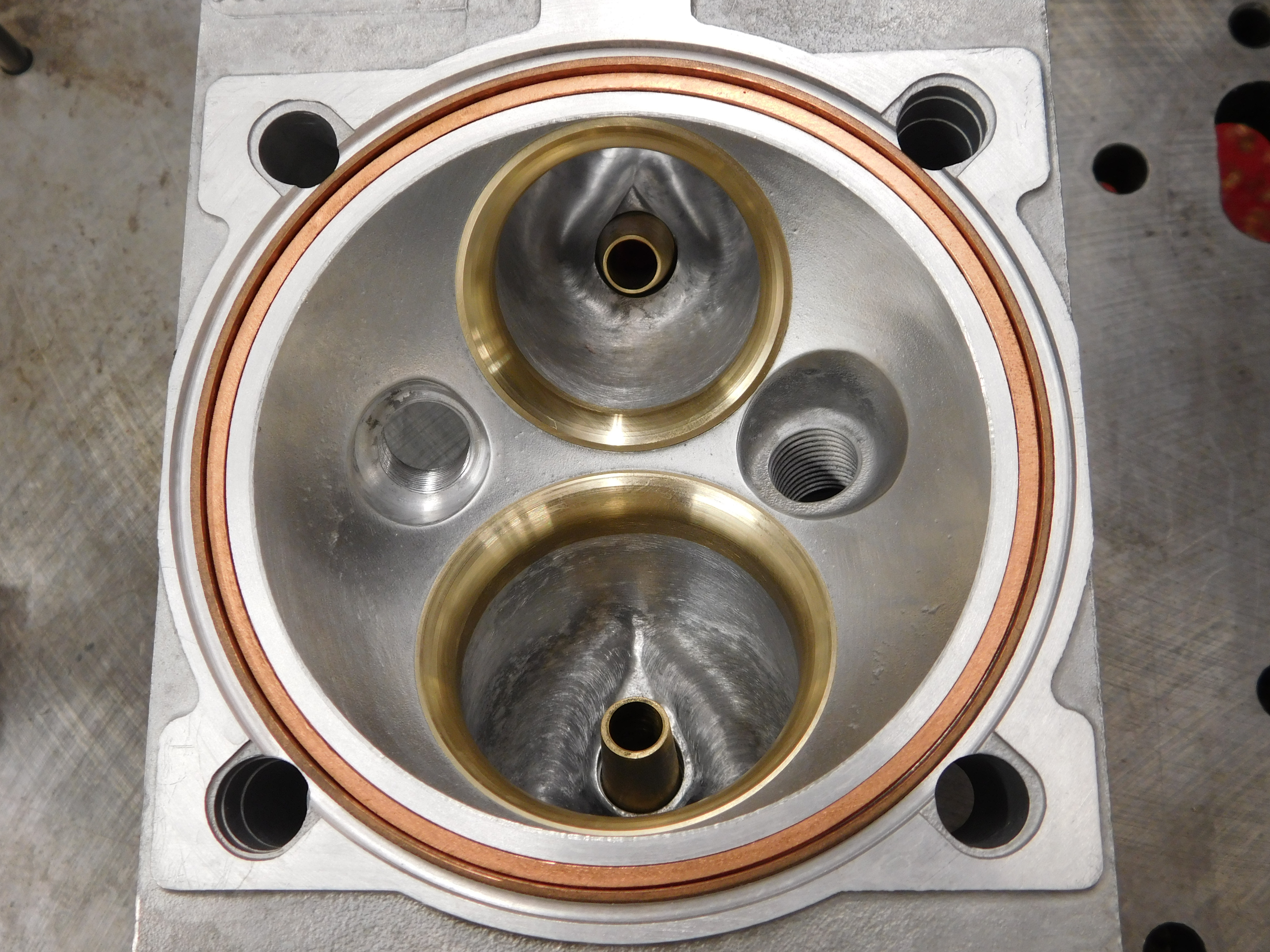

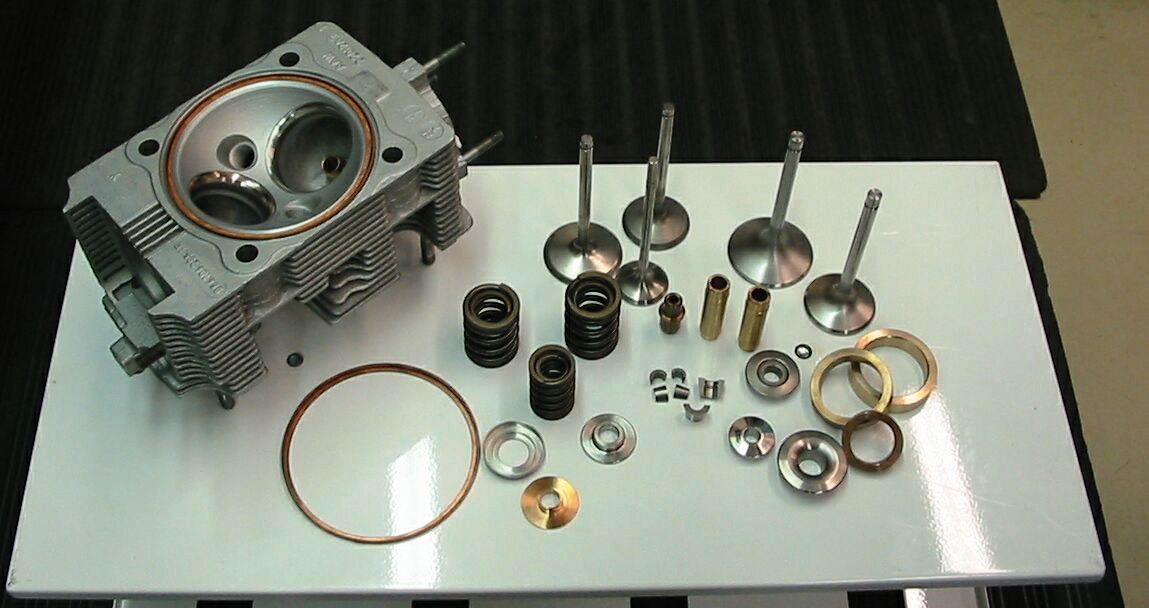

Our system uses two and sometimes three parts. In the case of the typical 911 engine, we use two parts. A sealing ring and a head gasket. The sealing ring acts as a seal between the head and the cylinder and the other ring is the head gasket. This ring takes all the punishment and acts as a barrier between the head and the cylinder.

Under running conditions, these two parts shift apart from one another and have a shearing action which often causes all the damage and wear. Cylinder pressure and head temperature cause the heads to move around and this causes the pitting and fretting often seen.

With the addition of the head gasket, the two parts are separated from one another and the head gasket does all the work. No further machining of the head is required, your head and cylinder surfaces stay intact, plus your static compression and clearances can all stay the same.

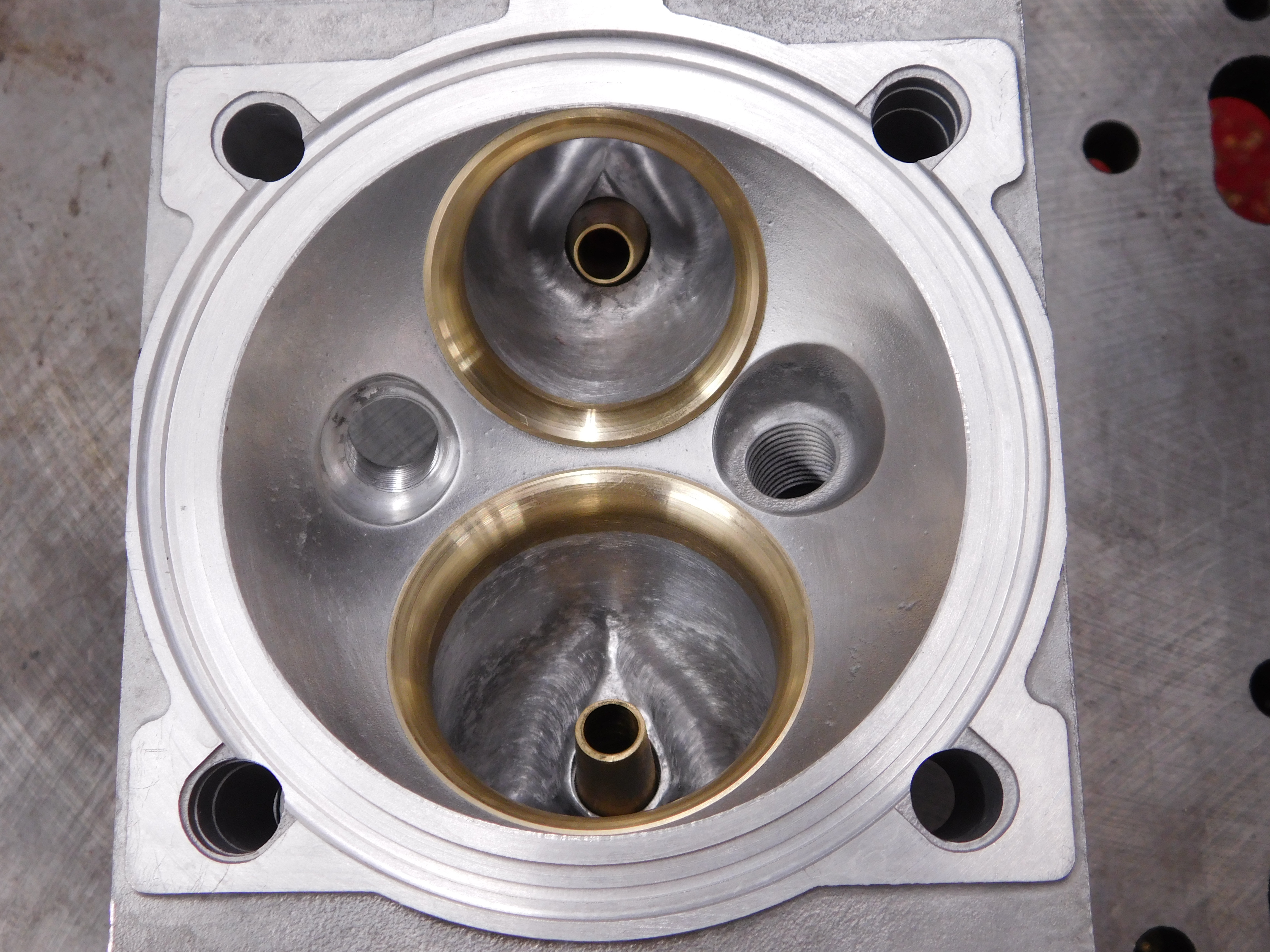

There is a machining operation required on both the cylinder and head for the sealing system.

We have sealing systems for the early 904, 356, 911, 964 and the 993 engines including the Turbo versions of these engines.

The photos here show the machining completed on the cylinder head and the gaskets in place.

If you have seen leakage between the heads and cylinders, then you are losing some of your compressed mixture that should be pushing down upon your pistons. This is lost performance.

If you want complete combustion and turn all that static compression into torque, then our sealing system is the answer.

Please see our services page for a full list of the machining services we offer.