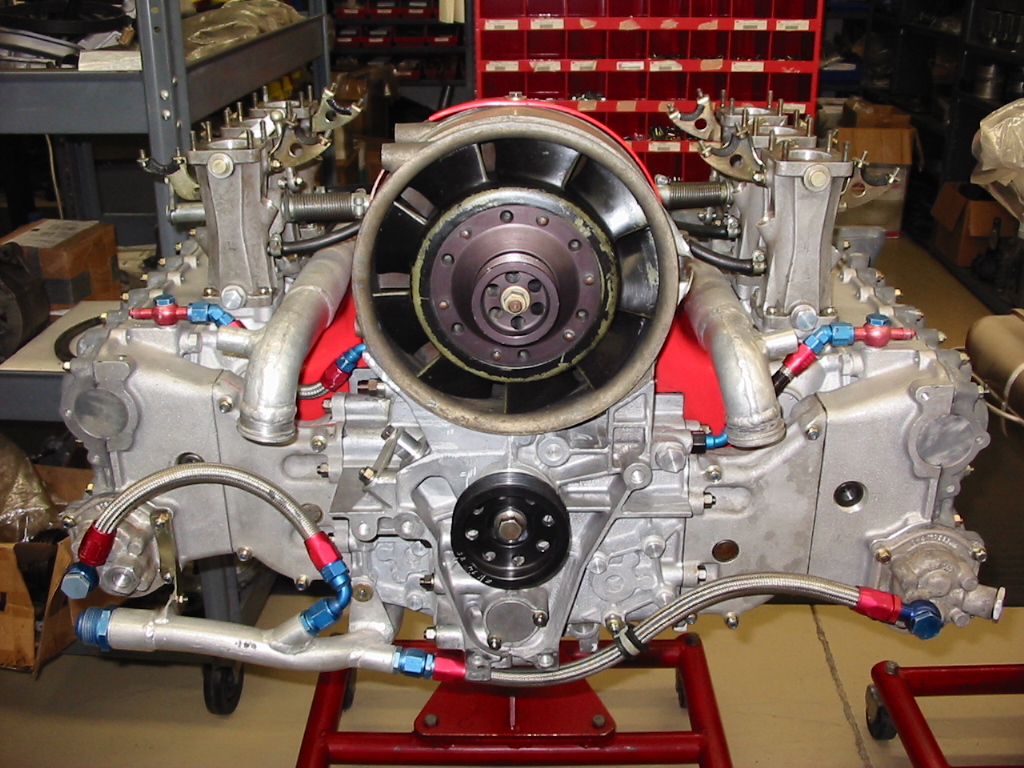

Porsche 956 Engine Rebuild

When undertaking these sorts of projects, you must remember you are an engine person and an artifact historian.

You have been tasked to restore and rebuild a piece of Porsche automotive history. These engines are extremely rare and very valuable. You must remember you are the custodian of this engine while it is in your care. What you do today will hopefully last for years to come. The engine will become a lasting example of what these engines were designed and raced as.

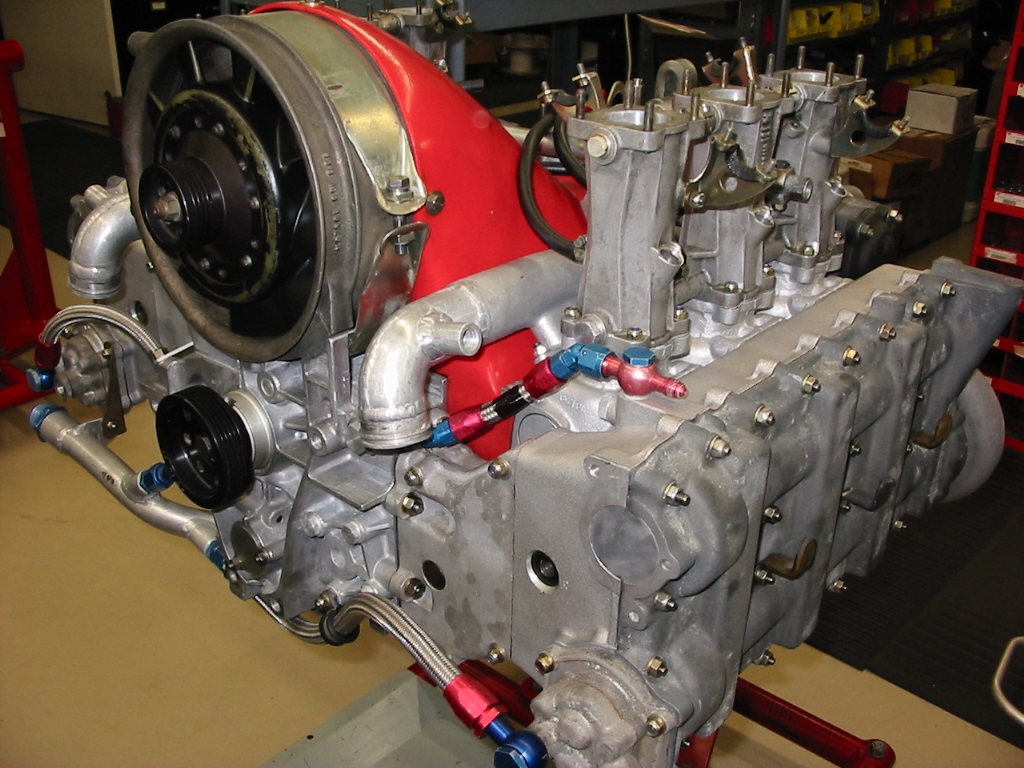

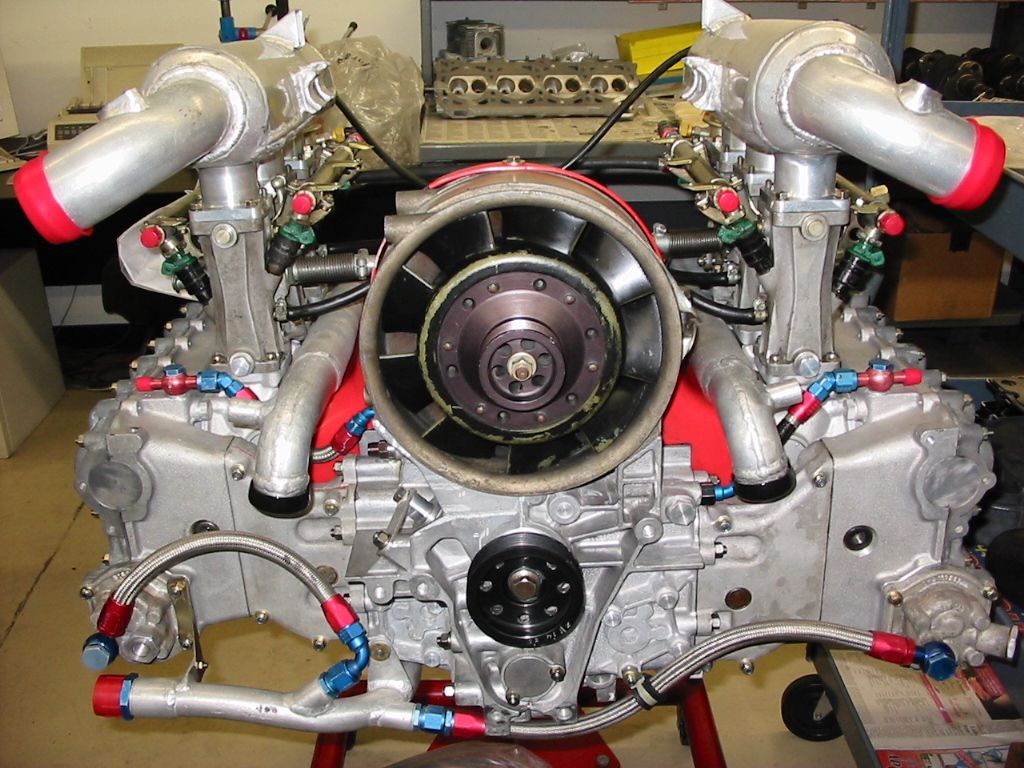

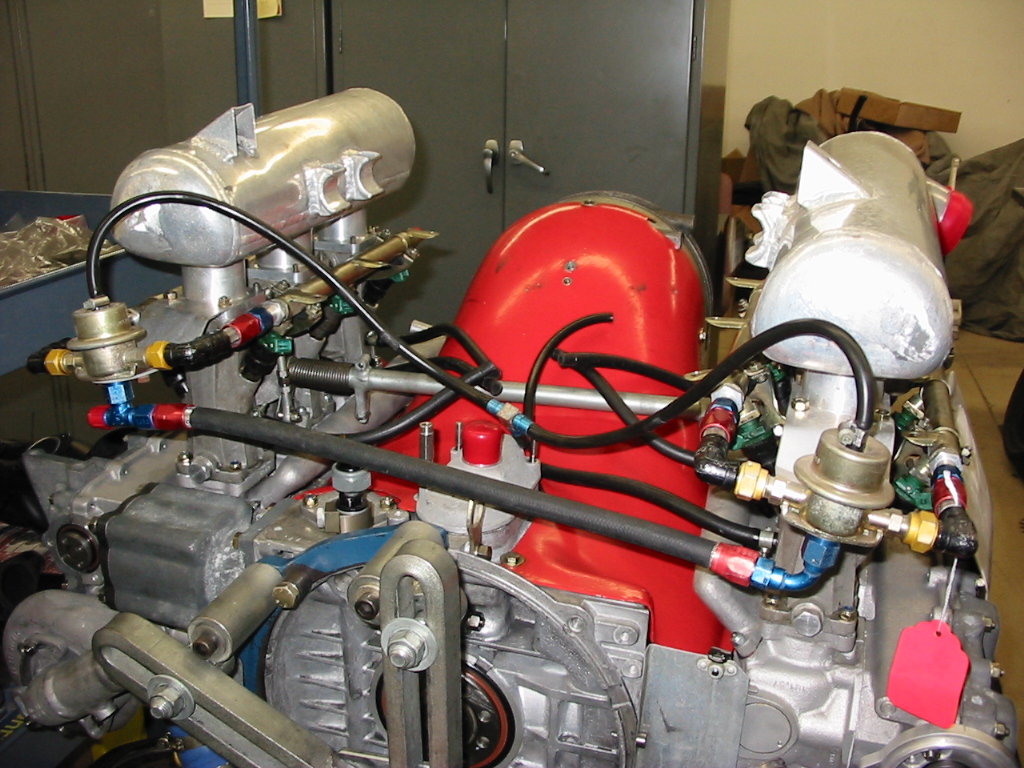

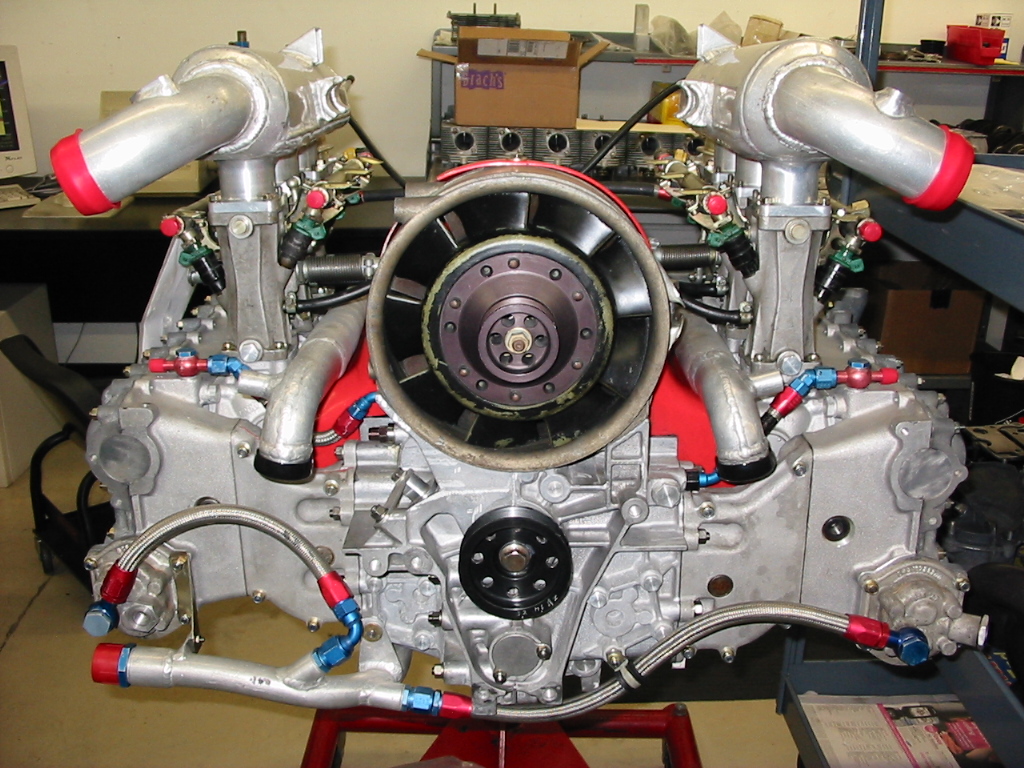

The 956 engine is a combination of the 911 air-cooled engine that used a basis for the race engines Porsche developed and the later water cooled engines. It uses both air cooled cylinders and water cooled heads. This technology was originally used on a derivative of the Porsche 935 race engine.

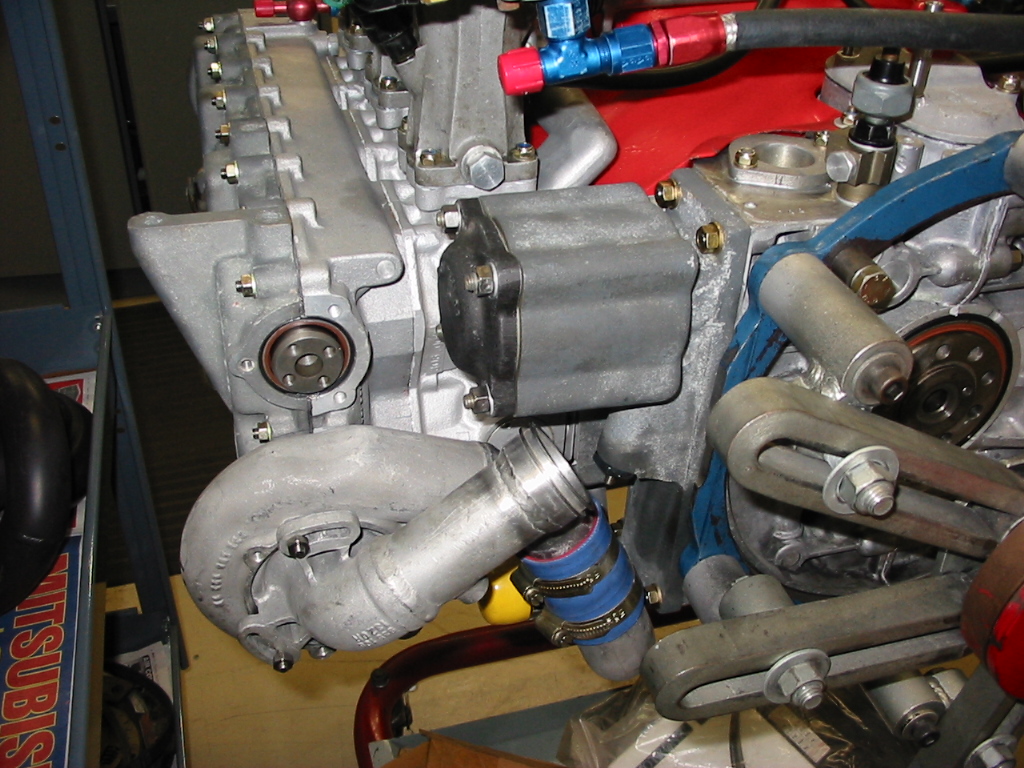

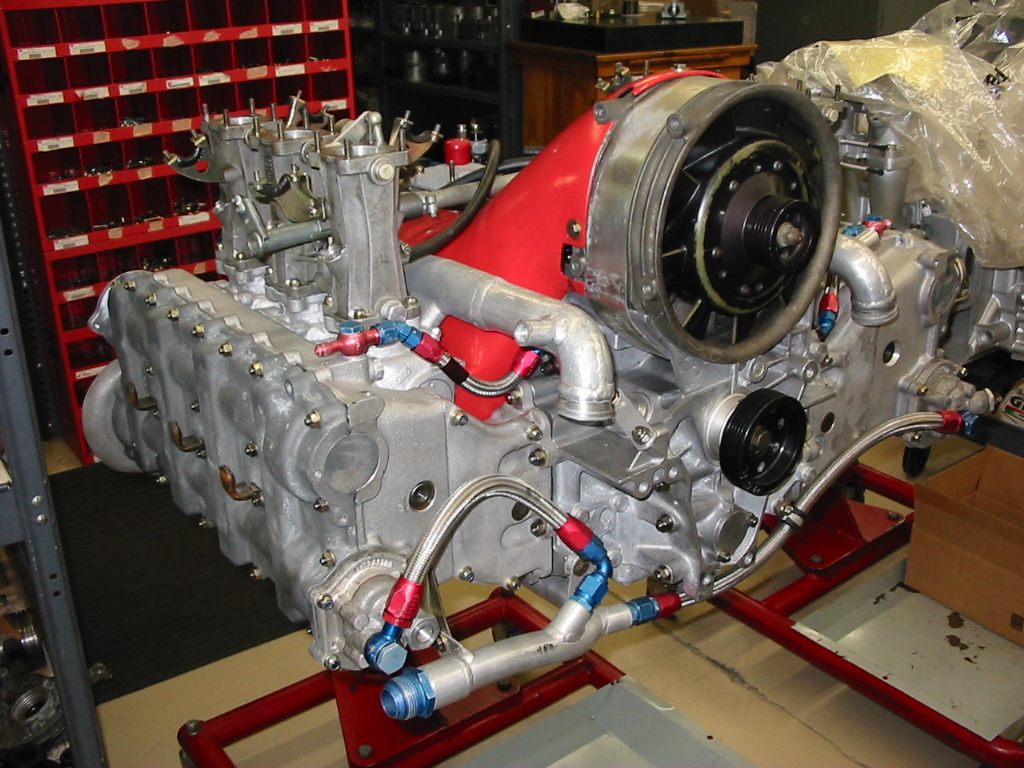

The bottom end of this engine is constructed like a typical 911 engine. The air-cooled cylinders are electro-beam welded onto the water-cooled heads. Two camshafts per bank operate two intake valves and two exhaust valves per cylinder. The camshafts are driven via gears direct from the 1st motion shaft driven off the crankshaft just like the 911 engine.

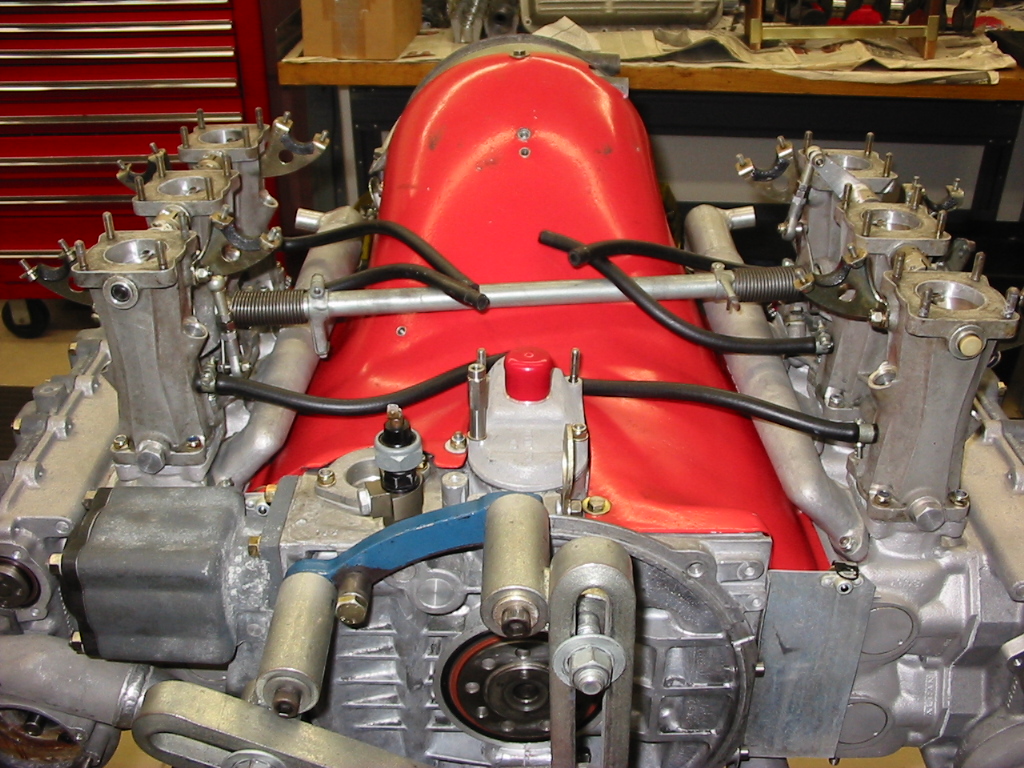

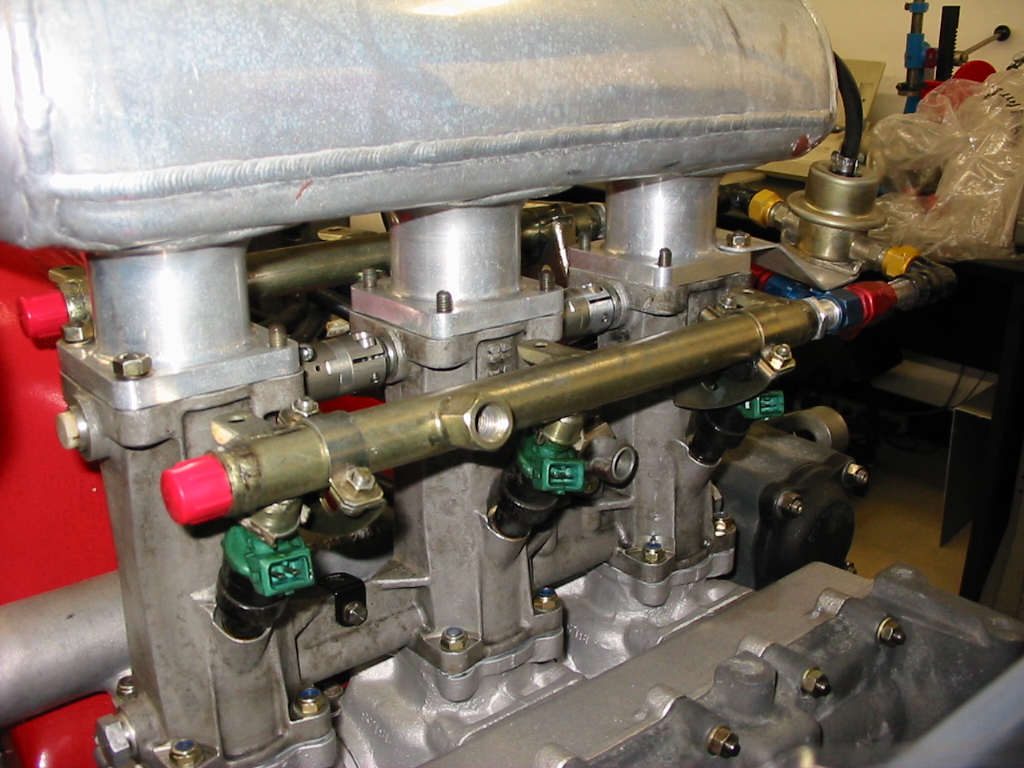

These engines originally used a very early Bosch EFI system that was extremely basic compared to today’s systems. The original 956 system used an ignition breaker points to tell the ECU when the throttle was closed or open. No TPS sensor. It was MAP based, non-sequential and used a distributor driven off the 1-2-3 side Intake camshaft for Ignition control. The water pumps were driven off the exhaust camshafts on either side.

Rebuilding one of these engines is typical of any 911 engine rebuild. The same disciplines in rebuilding any Porsche engine are required. Cleaning, measuring, low tolerance machining repairs and diligent assembly work are all necessary. The differences are the gear drives up to the camshafts that need care and attention for both gear lash and the axle pins the gears rotate around. The cylinder heads add some added degree of difficulty as the valve seat work and repair is done with the cylinders in place. So, all the seat work is done inside the cylinder unlike a 911-cylinder head. It takes special tooling that has a longer reach than what is normally used in seat repair work.

The valve train is a solid follower type with lash cap on the valve stem under the follower. 12 valves to lash and dual camshafts per bank to time via a Vernier adjustment on the cam gears.

Pictures of the cylinder heads and other engine parts can be seen in the 962C rebuild post in the past projects.